Product Design

Batch 1977-1979

(6 items)

Product DesignBatch 1977-1979

(6 items)

(6 items)

by Satish P. Raut

Bamboo is a natural material available in large quantities in our country. Since very ancient times, it has been used for building construction and for making many products. In recent times, it has been found that 80% of bamboo is used for papermaking. The value realised for bamboo in papermaking is very low. In addition, the private industry controlling the mills has indiscriminately destroyed the bamboo resources, affecting the large number of bamboo craftsmen traditionally dependent on bamboo as a raw material.

Bamboo, if used for products like furniture, can have an enhanced value for the craftsman, thereby increasing their self-employment opportunities. This would, of course, need structural support in marketing from the government. The design of a product or piece of furniture made of bamboo does not seem to have been tackled by a professional designer so far. With this background in mind, the present project on “Design of Bamboo Furniture” has been tackled.

by Sudhir Kumar Atreya

The most serious problem that vehicles today face is the fast-increasing price of fuel. In two-wheelers, petrol (gasoline) is the most commonly used fuel. Mopeds consume the minimum amount of gasoline as they are light and low-powered vehicles. So they could be very popular among the day-to-day users. But unfortunately, in Indian markets, mopeds are not sold well. They are very rarely seen on the roads.

Most of the two-wheeler users are young males, and for some reasons, they prefer to buy motorcycles or scooters. So the project started with “converting the possible buyers of scooters and motorcycles into the possible buyers of mopeds” as the basic objective. It was decided to give riding comfort priority. Other design aspects to be considered were visual appeal, functional improvements, ease of production, and maintenance.

by Gokhale V. S.

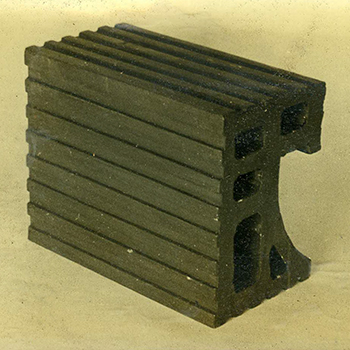

Earth, or clay, has been one of the basic elements of house building since the day man started living in man-made shelters. The earliest evidence of moulded lay is to be found in excavations of Mohenjo-Daro and Chanhu-Daro of the Indus Valley civilization. The various forms of moulded bricks being used in the construction of houses,streets, drains, etc.

Brick, wood, and stone were the major materials of construction in historic India. The very nature of these materials demanded prefabrication either near the site or construction or near the source of materials. Modern construction technology is also going more and more towards prefabrication and standardisation of building elements. With the growth of technology and science, prefabrication is no longer limited by external factors.

by Vinod Gupta

The selection of a material for a specific application is almost always a thorough, lengthy, and expensive investigation. Almost always, more than one material is a possible candidate, and the final selection is a compromise that weighs the relative advantages and disadvantages of all candidates. Service requirements such as toughness, adequate strength, dimensional stability, scratch resistance, heat resistance, non-toxicity, corrosion resistance, etc.; manufacturing requirements like formability, moldability, machinability, etc.; and various economic and market requirements should be met before finally choosing a material.

For an intelligent judgement or compromise in finally selecting a material, a thorough understanding of all materials and their various properties is required. No doubt there are thousands of books written on individual materials, processes, and their properties, but going through all of them for a quick reference in order to find the right material becomes a tedious and time-consuming process.

by Anil Saxena

Tools are extensions of the hand. They help to improve the capability of the hand. Through the use of hand tools, man has increased his efficiency and accomplishment. Most conveniences that relate to human comfort have been created by humans with the aid of tools. It is important to remember that the tools have a definite relationship to the happiness, comfort, and convenience of their users. It is remarkable that there has been hardly any change in the design or working principle of hand tools. If we were to compare some of the present-day common hand tools, If we were to compare some of the present-day common hand tools, we would find them practically the same as fifty-year-old tools.

With knowledge gained in fields like ergonomics and safety engineering, it is now possible to make our tools more comfortable and convenient. Also, there is a need to redesign existing hand tools. In this project, an attempt is made to redesign present-day woodworking hand tools. The whole project is divided into three phases. Information collection problem investigation and conclusion, design approach, and communication.

by Hemchandra Agashe

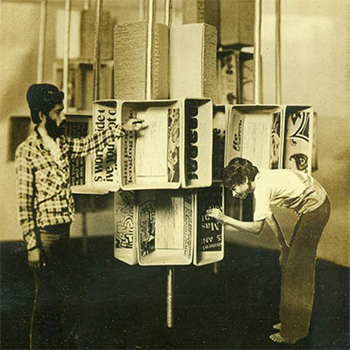

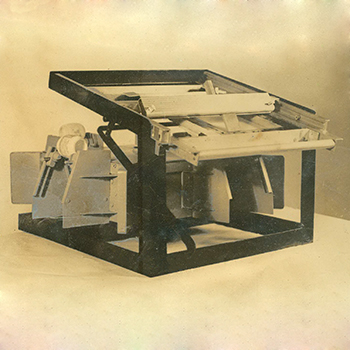

Silk screen printing process consists of forcing the special paint through the open meshes of the framed screen, part of which is filled up in solid so that paint can pass through those areas of the screen which are left open according to the design to be reproduced. Unlike most other forms of printing which are mainly confined to paper, this process can be reproduced on practically any surface and is used extensively for the decoration of furniture, textiles, plastics, ceramics, wall paper, glass etc.

Out of those base surfaces, this process is widely used on wallpapers when small batch and large size of the material is to be printed. In that case it is impractical and costly to use printing machines. On furniture and ceramics it is very often used mainly because of the depth or richness of the colour. On glass articles like glass tumblers and cold drinks bottles printing is done by screen printing method. But it is not as wide spread as printing of other surfaces mainly because of the requirement of heavy capital investment in furnaces and non availability of glass decorating inks in India. The other earliest use of screen printing was for textiles. In this process textiles are steam heated from below after printing is done. Thus textile screen printing is a different process.