Design Gallery

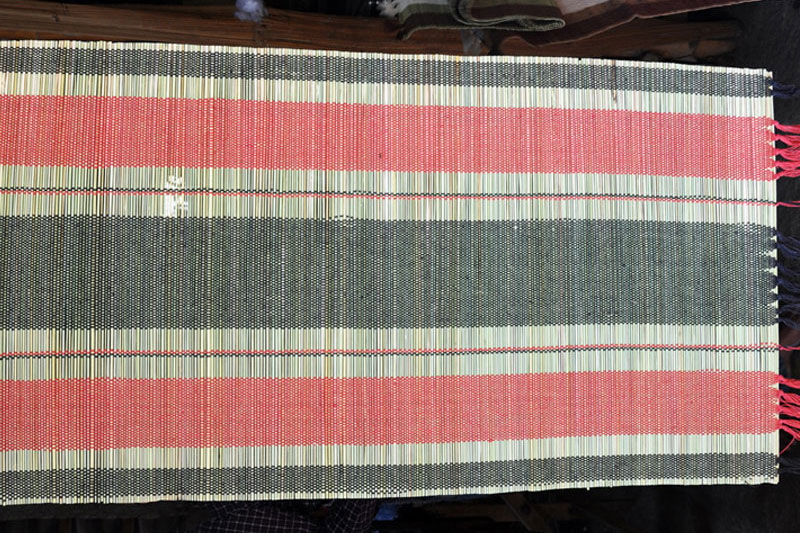

Banana Fiber Mat - Lakkavanahalli

The Craft of Making Mats

by

Banana plant provides textile fiber - The Banana Fiber. These fibers are obtained after the fruit is harvested by experienced women artisans. These fibers possess many characteristics which make their use advantageous, they are - abundance in nature, low cost, low density, biological degradability, renewability, good mechanical properties and non-toxic. Banana fiber is a great substitute for synthetic fibers, plastic and paper.

Artisans collect Banana bark from surrounding villages of Lakkavanahalli. Banana twine making is done in the streets preferably in the early morning. The bark is first split into small strips and soaked in water. Due to water treatment, the bark becomes smooth and soft. The strips are then hooked to the spinning wheel to make the lengthy yarn. As the spinning wheel starts rotating, the artisan walks backwards by adding the smaller strips of banana bark to form a long yarn. The yarn is reeled into small bundles and sent to weaving section for making mats and other eco-friendly decorative items. Minimum of 3 to 4 people required for yarn making. One person for operating spinning wheel and remaining for making twines.

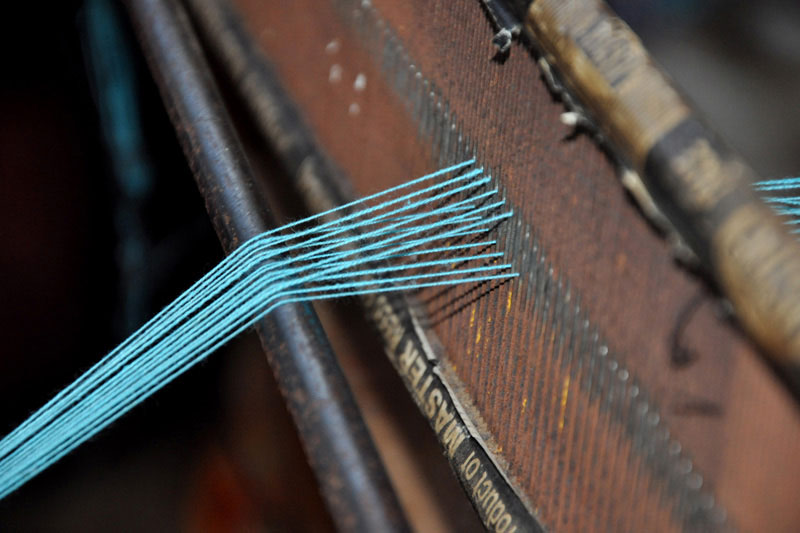

The mat weaving process is similar to other weaving techniques. Weaving is traditionally done in basic pit looms. The type of weaving practiced in Lakkavanahalli is very simple without using any Jacquard machines to create extra designs. The aesthetic look is created by using colorful threads, wool, kora grass and few other natural yarns.

For more details:

http://dsource.in/resource/banana-fiber-mat