Design Gallery

Ikat Textiles Handloom Weaving

Tie-Resist-Dye and Weaving

by

Ikat requires immense skills for detail of de-constructing the desired pattern according to the density of the cloth, winding threads on the frame according to the calculations made, covering selected sections of the weft for resist-dyeing and finally weaving. The entire process involves almost an entire family’s participation in different aspects.

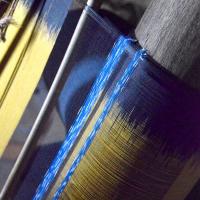

In Nuapatna sarees, the warp yarn is plain i.e. has no pattern. These warp yarns are interlaced by the tie-dyed weft (filling) yarns (kept in the shuttle) running along the width of the loom, producing the woven fabric corresponding to the design on the graph. Weft Ikat weaving is a slow process as the passes of the weft must be carefully adjusted to maintain the clarity of the patterns. Passing the weft shuttle 80 times to and fro weaves about 1 inch of fabric. Most weavers also combine Ikat pattern with a relief texture in the border of the saree (supplementary warp and weft weaves) that makes it a specialty of the region.

For more details: http://dsource.in/resource/ikat-textiles-nuapatna