Design Gallery

Taarkashi-Jaipur

The art of inlay craft

by

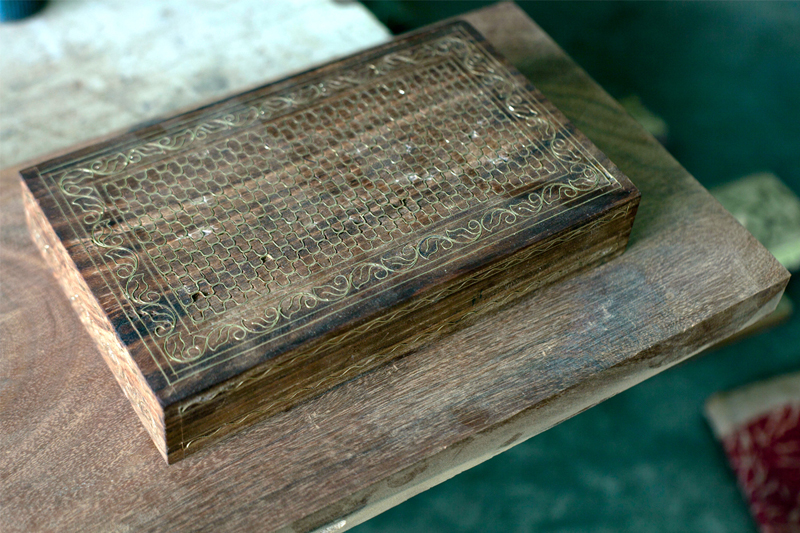

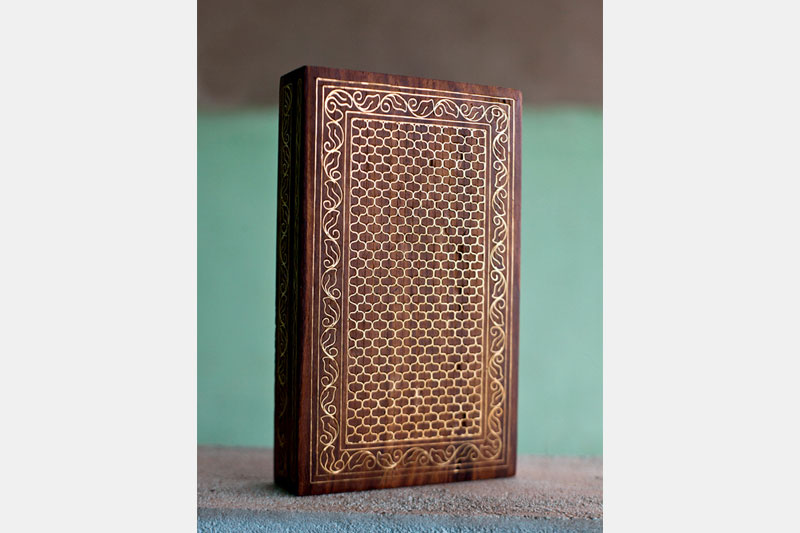

Jaipur is renowned for its rich heritage in metal crafts, particularly Taarkashi, a technique of inlaying thin strips of metal wire onto wood surfaces. The process begins with seasoning the wood to remove moisture, followed by cutting it into the required shape. Metal strips, known as taar, are marked, cut, and sharpened to create the inlay. Designs are either drawn directly onto the wood or printed on paper and pasted for guidance.

Artisans use a half-round chisel and hammer to carefully engrave the design, pressing the sharp edges of the wire into the wood while the thicker edges remain on the surface. Once the engraving is complete, the product is smoothed using Silli (a tool for sanding) and filled with Burada- a mixture of sawdust, Fevicol, and water—to fill in any cracks or grooves. After drying, the product is scraped, sanded, and polished with wax to enhance its finish and shine.

For more details:

http://dsource.in/resource/taarkashi-jaipur