Design Resource

Wood Carving - Name Plates

Craft of Wood Carving - Warangal

by

Prof. Bibhudutta Baral, Divyadarshan C. S. and Lija M. G.

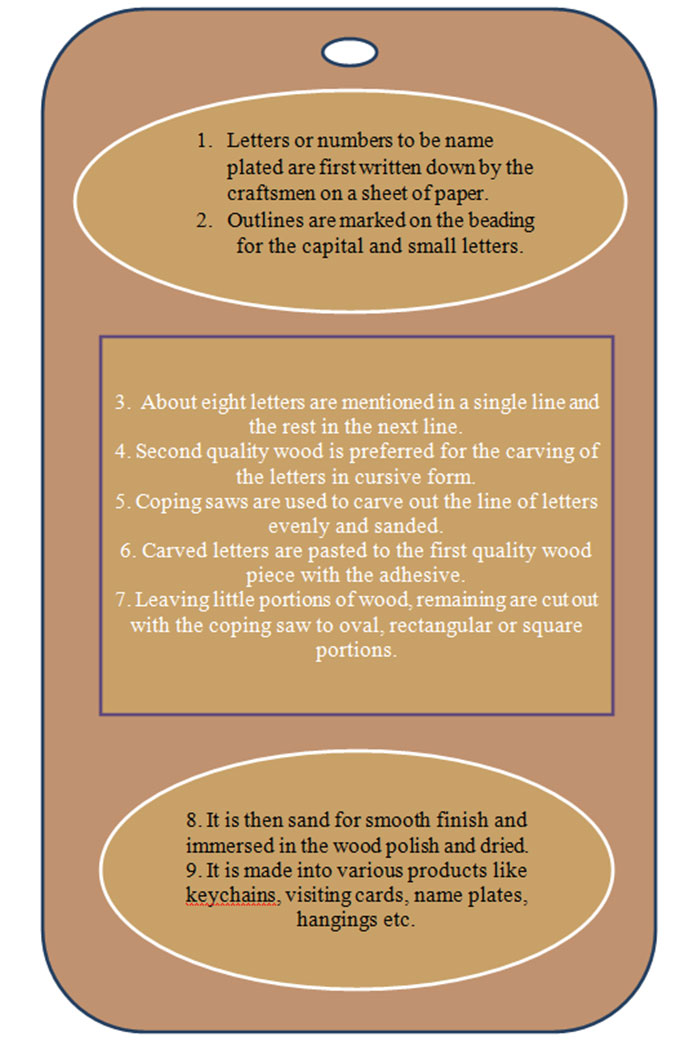

Craftsman writes down the design to be carved on a sheet of paper and by this he understands the space required. The outlines are marked on the beading/ plywood about 8 letters are mentioned in a single line and next set of letters in the next line with letters in a flowing manner like the cursive writing. Generally the second quality wood are preferred for carving of the letters that has more of the white surfaces. With the help of coping saws the line of letters are carved out evenly and rubbed on the sandpapers for the smooth (outlines) surfaces.

The craved letters are placed on the first quality beading / wood pieces that has the fine grains on it. The letters are stuck to the surface of the first quality wood with the glue (adhesive) that fixes both the wood pieces together. Little part of the wood is kept and the remaining parts are cut out with the coping saw keeping on the stand fixed which was specially made by the craftsmen. The outlines are either cut in an oval, rectangular, square or shapes of choose of the craftsmen and then sanded for a smooth finish. The completed name plates are then immersed in the wood polish to obtain a good finish and dried for some time. Later on these are made to different products like keychains, visiting cards, name plates, hangings etc.

Flow Chart: