Design Resource

Saree Weaving - Sambalpur, Orissa

Ancient Handicraft

by

Prof. Bibhudutta Baral, Divyadarshan C. S., Manasa K. H.

The process of making a Sambalpuri Saree consists of three major steps:

1. Raw Yarn degumming

2. Dyeing/Coloring

3. Wrap/Weft

4. Weaving

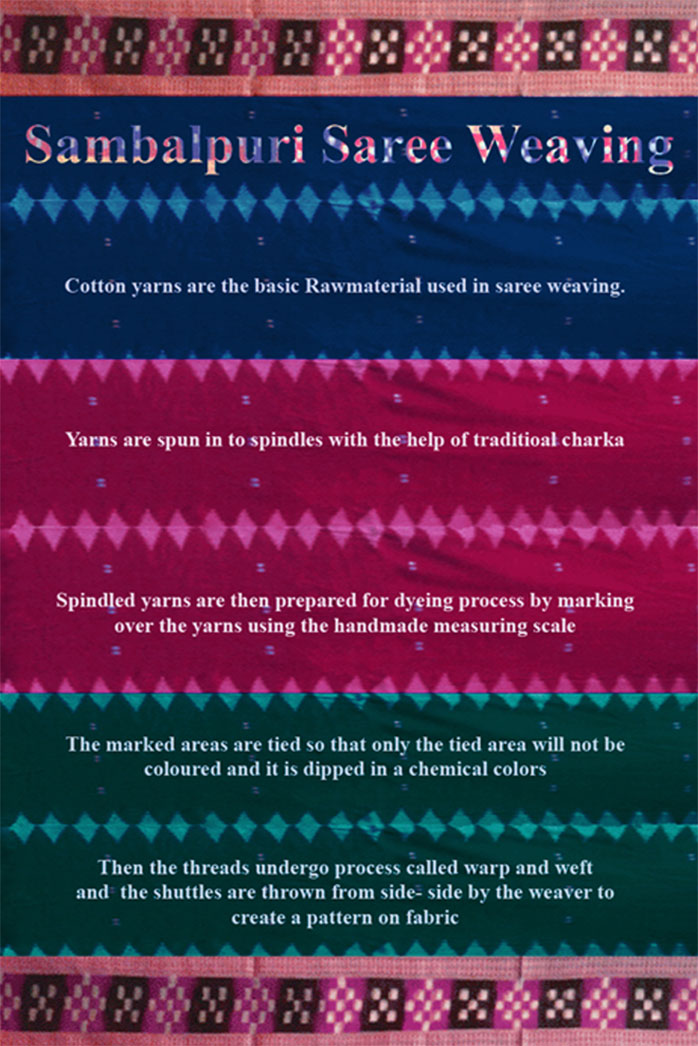

The process sequences followed during weaving are described as below:

The raw material used for all the products are 100 percent cotton, which are brought from the local dealers of Orissa. Sambalpuri fabrics have their original style of craft known as Baandha. Traditionally, craftsmen created Baandha with images of flora or fauna or with geometrical patterns. Baandha fabric is created using a tie and dye technique.

In early times sambalpuri sarees were dyed using naturally extracted colors such as leafs, fruits, stems, roots, muds and outer cover of tree. They were using the following elements to get the respective colors as mentioned below mud – Brown color, Teak wood- Red color and mango nut for Black color. But after the synthetic dyes became available to them they abandoned the usage of natural material and adopted the synthetic dyes which are available in market.

Sambalpuri sarees are known for its geometrical designs and sober colors. Yarns are brought from the market are spun in to winded with the help of traditional charka. Winded yarns are then prepared for dyeing process by marking over the yarns using the handmade measuring scale.

The marked areas are tied so that only the tied area will not be colored and Yarn are then boiled in soap water to increase flexibility and texture and then it is dipped in a synthetic ready colors which are bought from the market. To develop another color in the design the colored portions are tied and the portion on which the second color has to be developed are untied and dyed in the second dye. In this manner a number of colors are developed. These threads are so woven to desire design. Designs produced in this method differ from printed and jacquard woven designs as the figures by later process can be had only one side of the cloth. After the yarns are dyed, it is dried for some time and it is spindled using spinning wheels so that the required size of the yarns are then cut from the wheel and those threads undergo process called warp and weft where the threads are measured to the needed length of the fabric to be woven. The wrap threads are then loaded to the bean. The bean is put to the loom and knotted to the old ones in the loom to begin with process of weaving.

A handloom saree is often woven on a shuttle-pit loom that made of ropes, wooden beams and poles. The shuttles are thrown from side- side by the weaver. Other weavers use a fly-shuttle loom which can produced different types of patterns. The sarees can vary in size and quality.