Design Resource

Saree Weaving - Thrissur, Kerala

Traditional Wear of the Kerala

by

Prof. Bibhudutta Baral, Divyadarshan C. S. and Amulya S.

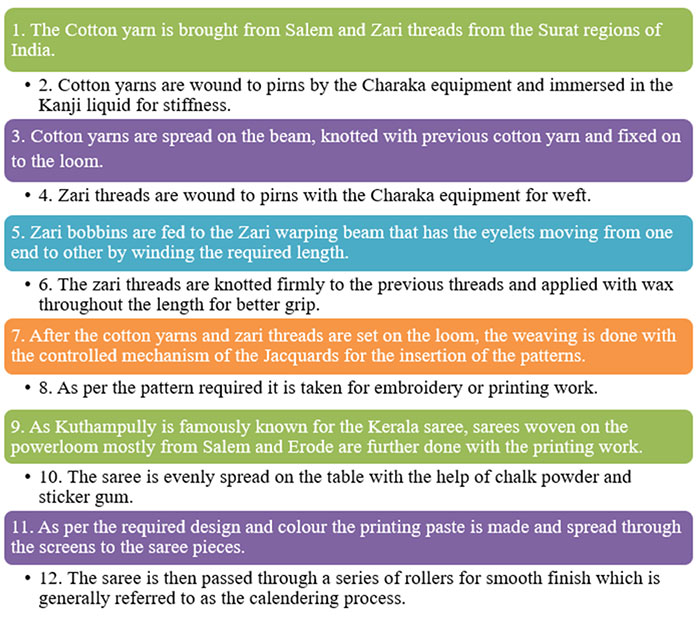

Kerala saree is specially known as the saree of either white or cream with kasavu (golden threads). The process of making this saree involves the constant hardships of the weaver during all the steps of making it. Cotton yarns are generally brought from the Salem regions of Tamilnadu and Zari threads from Surat. The cotton yarn of the roll form are wound to the small pirns for the weft purpose and immersed in the kanji liquid for stiffness purpose. Zari threads are wound to the small pirns for the design and weft purpose.

In case of the cotton yarn they are rolled on the beam and knotted to the previous yarns firmly by dipping the fingers into the melted wax to avoid the slipperiness of the fingers. The yarns are then extended and the beam is placed on the loom for weaving.

Zari threads from the bobbins are passed through the eyelets and rolled on to the warping beams. The eyelets moves from one end to the other end of the warping frame, there by winding about three mona said in the local language (i.e. one set of the top and the bottom threads of the warp). Thereby continuously changing the bobbins till the required length is obtained. The zari threads are then knotted to the previous threads and in between dip the fingers in the melted wax for the strong knotting. The zari threads are extended and applied with wax from one end to the other for stiffness purpose. After the cotton yarn and the zari threads are inserted and tightened to the required length. The weaving process begins with the controlled mechanism of the Jacquard for the insertion of the patterns.

Though weaving is done on the handlooms mostly, the saree woven on the power looms from the Erode and Salem regions are brought to Kuthampully for the final works of the printing. The method followed is the screen printing where the films of the designs are sent from Tirupur and the screens are set here. As per requirement, the screen is cleaned properly with the wet cloth and then the colour paste made is spread evenly to imprint the design on the fabric that is placed firmly to the table with the chalk powder and the sticker gum.

Most of the time the fabric observed is rough therefore they are sent through the calendering process to obtain a smooth finish. The fabric is then folded, pressed and packed to be sold or exported to the places wherever the Keralites live in the world.

Flow Chart of Saree Weaving Process: