Design Resource

Chunar Red Clay Pottery - Mirzapur

The Art of Handling of Clay

by

Prof. Bibhudutta Baral and Aakash Sharma

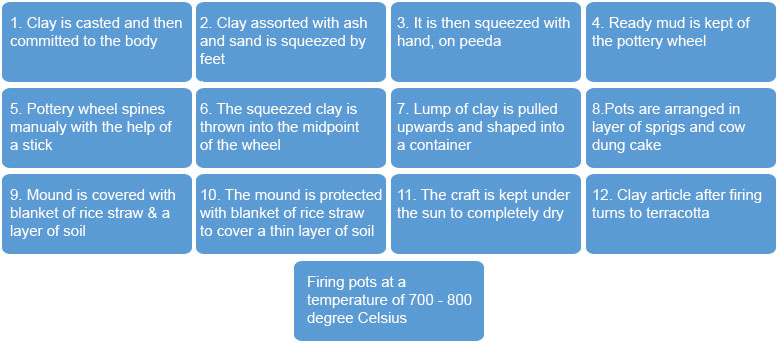

The structures, which are mandatory for a variety of uses, are turned on the wheel. The convinced portions such as the nozzle or the handle are left out. Clay is casted unconnectedly and then committed to the body. After it, incising patterns on the surface for making geometrical patterns ensures the decoration. The clay assorted with ash and sand is squeezed by feet, collected and cut with lahasur. It is then squeezed with hand, on peeda and a lump is completed. All the compact particles are removed and ready mud is kept on wheel for producing various forms. A potter’s wheel has small sports, turns on an axle of hard wood or metal and is postulated with a large hub, which acts as a rotating table.

The potter throws the squeezed clay into the midpoint of the wheel, and spins the wheel around with the stick. Due to the centrifugal strength the lump of clay is pulled centrifugally and upwards and shaped into a container. This is dragged out with a string, dried and aflame in a potter’s kiln. Clay article after firing turns to terracotta.

The pots are fired in simple open-pit kilns that are very efficient and inexpensive for firing pots at a temperature of 700 - 800 degree Celsius.

The pots are organized in layers of pots; a layer of sprigs, twigs and cow dung cake is sometimes additional. The mound is then protected with a blanket of rice straw, which, in turn is enclosed, with a thin layer of loamy soil. The firing takes four to five hours. Black, red and yellow clay are castoff for making terracotta objects.

The measureable is mixed properly and dehydrated under the hot sun so that any sort of dampness, if present, may evaporate.

Then the mixture of wet clay is filtered through a fine sieve to remove pebble.

After giving figure with hands the items is then baked in the improvised kilns sheltered with cow dung cakes, fuel and saw dust etc. This is pulled out with a string, dried and fired in a potters kiln.

Flow Chart: