Design Resource

Metal Bells - Kutch, Gujarat

Metal Artwork

by

Prof. Bibhudutta Baral and Ranjitha M. C.

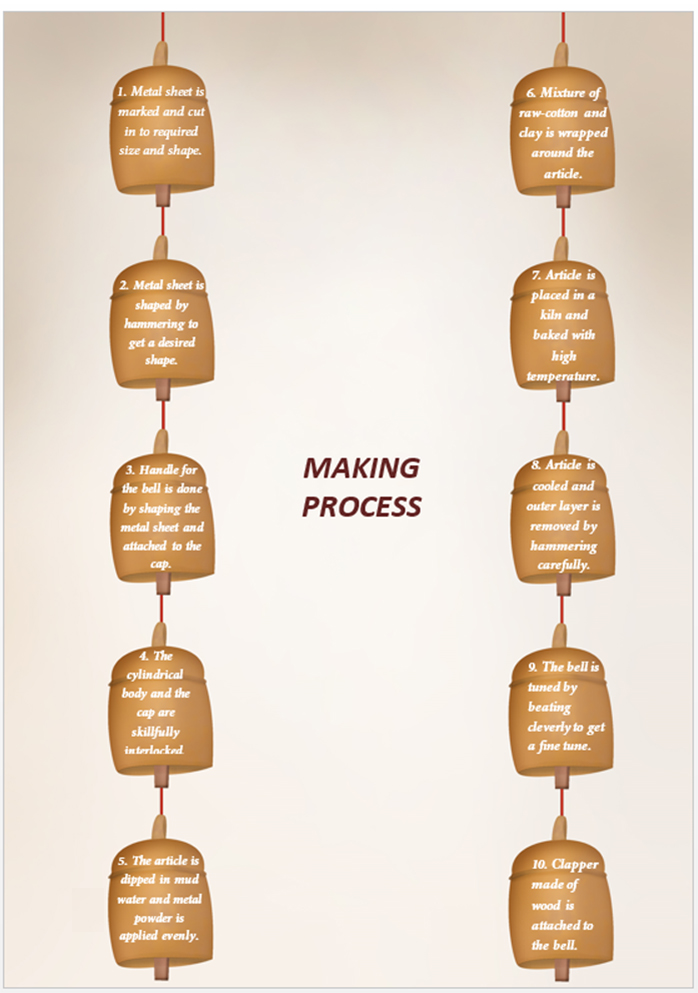

The metal bells are manufactured in the traditional process of heating and beating. In India it is believed that the bell sound will drive away all the negative thoughts. In Hinduism and Buddhism, bells are used in religious ceremonies and bells are also called as ‘Ghanta’ in Sanskrit. Before these bells were made in Zura but as time passes this craft spread to some other places like Nirona and Bhuj etc. Iron sheets, metal powder and mixture of raw cotton and mud are the basic materials for bell making that include five important steps those are shaping the metal sheet, applying metal powder, mud wrapping, heating and tuning.

Initially iron sheet is marked according to the required size and cut with the help of metal sheet cutter. The edge is cut slightly to lock both the edges to make cylindrical hollow. Then the metal sheet is shaped by placing on the rock, which has an impressions of varying sizes and shaped carefully. Metal sheet is beaten further and smoothen the edges, which has to be overlapped. Once again the sheet is marked in to circle using metal compass to make a cap for the bell. The marked sheet is cut and bent by hammering the sheet to obtain a dome shape. The sharp edges are smoothened by hammering. The handle for the bell is made by cutting and shaping the metal sheet according to the bell size. Handle for the bell is attached by making a hole on the semi-circular hollow crown. Then the cylindrical body and the semi-circular hollow crown are skillfully interlocked together without any welding but are beaten and driven in to the required shape.

Woman in the house will do the next process. The article is dipped in to mud water and then the metal powder made of copper and zinc waste pieces applied on the wet bell so that it will hold the powder smartly. Then the mixture of raw-cotton and clay is kneaded thoroughly and wrapped around the article. Once done with the wrapping, the article is placed in kiln using metal holder to bake with a high temperature. After heating the article is taken out from the kiln and cooled by dipping and pouring water. Then the outer layer of mud is removed by hammering carefully. The wood is cut and shaped in to required size to make a clapper for the bell. Then the clapper for the bell is attached with the help of metal wire. The very next step is tuning the bell, which is one of the most important processes. Artisan starts tuning the bell by beating cleverly to get a fine tune.

Flow Chart: