Design Resource

Banana Fibre Doll - Kanyakumari, Tamilnadu

Eco-Friendly Fibre Doll

by

Prof. Bibhudutta Baral and Sowmya B. N.

Banana fibre processing involves the following steps. The extraction of the natural fibre from the plant required certain care to avoid damage. Initially the banana plant sections were cut from the main stem of the plant and then rolled lightly to remove the excess moisture. Impurities in the rolled fibres such as pigments, broken fibres, coating of cellulose were removed manually by means of comb, and then the fibres were cleaned and dried. After drying the fibre is ready to use.

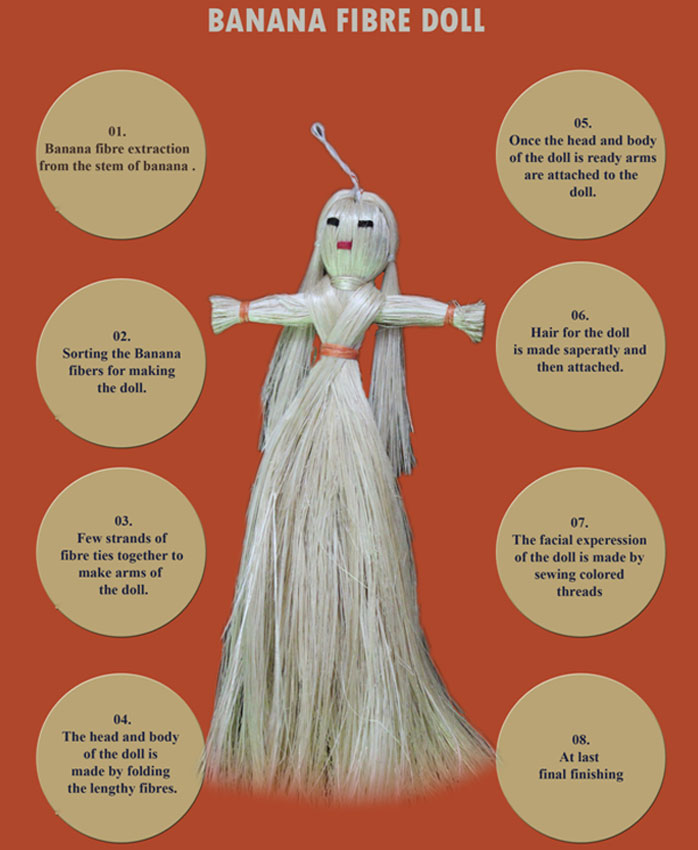

The process of making this craft is very simple. Initially the required amount and required length of raw banana fibre is taken and sorting the banana fibres for making the doll. Then the thread is tied on the middle portion of the raw fibre. Lengthy fibres are folded in such a manner where it forms the head and body of the doll. Once the head and body of the doll is ready arms are attached to the doll. The arm of the doll is made by separately and then attached together. The required length of raw banana fibre is taken for arm making and the coloured thread is tied at both the ends of the raw fibre and then attached. Once the basic shape of the doll is achieved detailing like hair are stitched together. Then facial features of the doll is made by using the colored threads by sewing. Once the facial features of the doll is completed the hair for the doll is attached. Hair for the doll is prepared by taking few strands of raw fibre and tied at the middle. Then the prepared fibre is attached at the head of the doll and stitched together. Once the making process of doll is completed the fibres are trimmed at the ends evenly to give final finishing.

Flow Chart: