Design Resource

Gaddi Blanket Making - Himachal Pradesh

Woolen Blanket

by

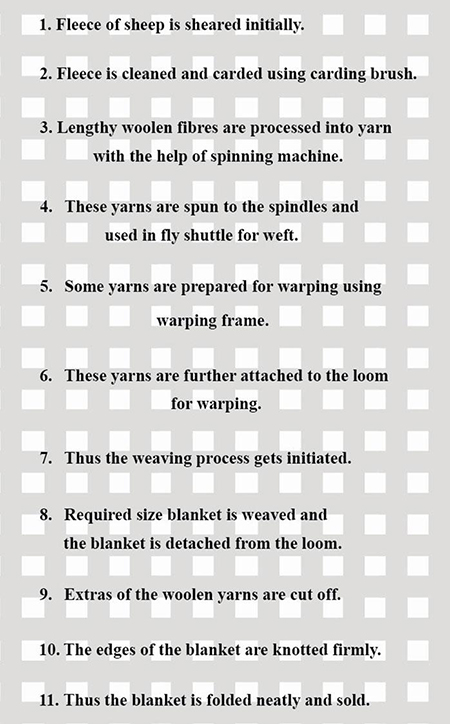

Gaddi making process begins with the peeling of thin layer skin and shearing of the fleece of sheep. Usually, the yarn is peeled during the hot weather. The shearer does this process of shearing the fleece off. The fleece is then cleaned using a wool carding brush, as the raw fleece contains manure, natural oil, etc., that has to be removed thoroughly. The long-staple wool fibers are processed into yarn with the help of a spinning machine. Thus, the yarns are further wrapped around the spindles. These spindles are additionally put in a fly shuttle for weft yarns. And some woolen yarns are prepared for the warping process. It is made using a warping frame. Once the warping yarns are set, they are attached to the loom. Thus, the weaving process gets to begin. Warping yarns are the length of the fabric that is being weaved using the fly shuttle with the loaded pirn for the weft process. Here the cross threads that pass from one side to another under the warp threads to make a fabric is called the weft. Accordingly, the blanket is weaved, and the extras are cut off. The product is detached from the loom, and the edges of the blanket are tied firmly. These are then folded and sold.

Flow Chart: