Chapter 1

Introduction

It is impossible not to notice one or more sheet metal objects at any given time in and around our work environments. From a hairpin, bottle cap, utensil, appliances to cars, airplanes, railway coaches, and many more, sheet metal’s presence and association in everyday living is a fact of life. However, not much is known to everybody as to what goes behind before a sheet of metal turns into an object.

Sheet Metal, steel to a large extent, aluminium, stainless steel followed by titanium, brass, copper, exotic materials like gold and silver are present practically in every industry in some form or other. Sheet metals have more applications than virtually any other materials in the manufacturing industry. From cooking utensils to seatbelts, bridges to automobiles, cabinets to ornaments, these sheet metals are found as products everywhere.

The advantage of sheet metal is its higher strength-to-weight ratio. It is also strong and durable as compared to other contemporary materials like wood and plastic.

This document aims to briefly expose sheet metal fabrication technologies in product design to novices and professional design practitioners. It is aimed at explaining different types of materials and fabrication technologies that are commonly used. This study material also attempts to illustrate examples closely related to product design rather than general fabrication.

There is a misnomer that sheet metal in a general fabrication sense is crude and lacks finesse. Sheet metal offers much better scope than plastics in reaching out to customers quickly in wide appealing varieties.

1. Broad product areas using sheet metal

- Electrical, Electronics

- Automobile

- Furniture

- Domestic Utensils

- Exhibitions

- Signage

- Gifts, Novelty

- Packaging

- Construction

- Transportation, to name a few

2. Examples of sheet metal products in everyday use – Mini to Mega

Engineering products are not inert. They do not lack the strength to evoke feelings. Every product we come across in everyday life has its own character. The efforts of engineers and designers ultimately culminate in a product is not that not only functional but also enjoyable to feel and even perplexing at times.

Small Instruments

Domestic Artifacts, Utensils, Appliances

Novel

Novel Utility

Utility Appropriate

AppropriateHousings and Enclosures

Furniture

Automobiles

Aerospace

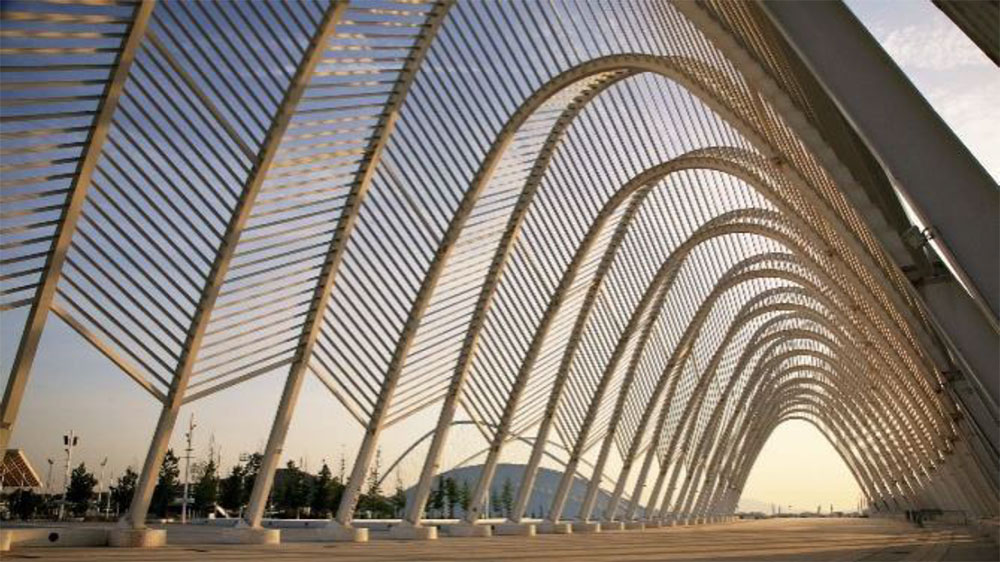

Construction

Art

Beautiful (Image source)

Beautiful (Image source) Strong (Image source)

Strong (Image source)3. Manufacturing Methods

There are three types of productions involved in any manufacturing activity. They are,

- Mass Production

- Batch Production

- Custom Production

Mass Production

Consumer Items small and big, are produced in large quantities

Mass production is where goods of the same type are produced in large quantities. In such cases, Capital Expenditure (CAPEX) on tooling is high. Operational Expenditure (OPEX), i.e., the production cost is low. Examples being automobile parts, Consumer goods, Utensils, Tools, etc. In mass production, manpower skill requirements are low.

Mass production involves moving the product part through a series of pre-determined stages continuously for processing and achieving a higher rate of production. This involves systematic planning in setting up the production line. The risk being, if there is a quality defect somewhere in the line, the entire line production of a production line is affected.

Batch Production

(Image source)

(Image source)

Predominantly industrial items, produced in batch quantities

Batch production is where goods are produced in batches as per the given specification for each batch. CAPEX in batch production is low, and OPEX is medium. Examples are enclosures, cabinets, and the like. In batch production, the manpower skill requirements are medium level when large, medium-size products such as machine enclosures, electrical and electronic cabinets involving batch production, and sheet metal are the most preferred material for fabrication purposes.

In batch production, a group of product parts are made at one place and moved from one workplace to another workplace in a “batch.” This method or production normally involves universal machines which are easily modified to process different components. One advantage of batch production is better quality control. Each batch is checked for quality before moving to the next stage. If there are quality issues, only a batch is affected by the entire lot.

Custom Production

One off item, produced to custom specifications

Custom Production or One of type involves just one or very few numbers produced mostly on highly customized specifications. Examples being Ship Bodies, Engineering Structures, Sculptures, and Handicrafts, etc. Custom production practically eliminates any kind of CAPEX but is high on OPEX. Manpower skill required is also high on the scale. There will be a lot of fluidity in the entire product building process. This requires continuous updating of information and change of plans.

Sheet metal is extensively used in any of these manufacturing methods. More than 60 % of raw materials in industrial production are sheet metal-based. Once the nuances of working with sheet metal are understood, it is left to the imagination of designers to explore endless interesting designs.

3.1 Example of creative designs unique to Sheet Metal

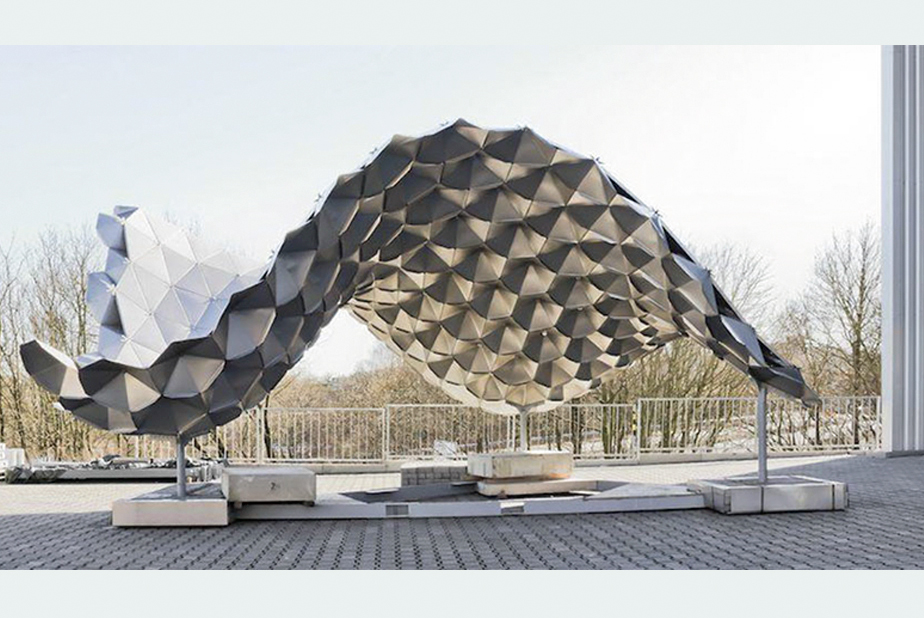

(RWTHAACHEN University).Tessellation techniques are well-made use of in this self-supporting structure.

Sheet metal processes such as intense strength characteristics, complex freeform architectural shapes can be conceived using modular elements which are interlinked, and the whole structure made self-supporting. The combination of tessellation and folding enables the generation of freeform structures using sheet metal.

4. Some practical examples

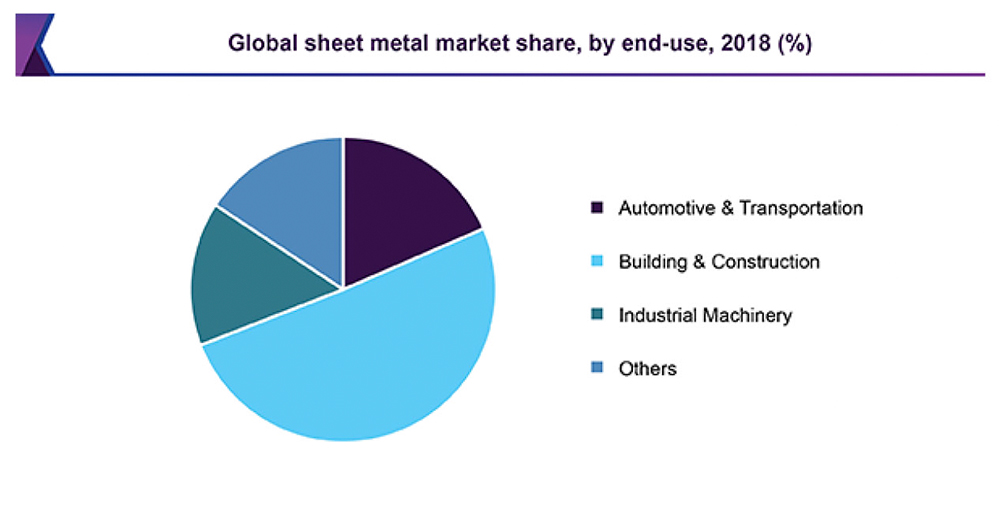

The global sheet metal market size was valued at USD 265.0 billion in 2018 and is projected to grow at a compound annual growth rate (CAGR) of 5% till 2025. Its versatility is such that it finds applications virtually in every conceivable manufacturing sector.

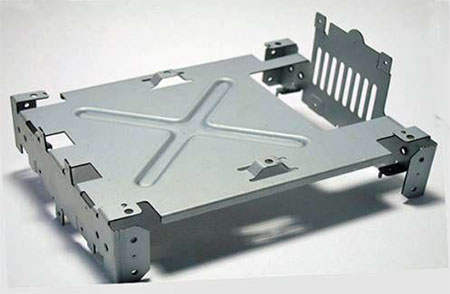

Equipment Chassis

(Image source)

Sheet metal is an invaluable material in producing intricate shaped one-piece chassis for electronics housing. There is no other material that matches this kind of complexity in a cost-effective manner. Holders, clamps, tabs, and many other features are incorporated in this one-piece chassis part.

Aircraft Seat

(Image source)

Sheet metal is one material that possesses properties to strengthen itself with simple techniques. In this example, a simple embossing process is effectively used to strengthen the seating and backrest areas which otherwise would be flat surfaces prone to cambering and distortions.

Decking

(Image source)

Roof decks made out of sheet metal allow large spans without buckling with inbuilt provision to fix flooring material. They are used in flat, pitched, or arched roof systems. Besides, profiling allows easy underneath cable routing.

Designer Stationery

(Image source)

Designer tableware is increasingly becoming popular in use. They are no more pricy because of their novelty. Due to volume production, the prices of such artifacts have become affordable and their use is widespread. The pen stand shown here has actually undergone through many precision manufacturing processes yet their prices are very low due to modern sheet metal processing techniques.

Storage Racks

(Image source)

Sheet metal possesses amazing strength characteristics. The items which were once used to be produced by heavy structural materials involving rigid welded joints are now produced in sheet steel and with flexible joints. With proper design considerations, they are capable of carrying large amounts of loads.

Roofing Sheets

(Image source)

Sheet metal roofing sheets have replaced conventional roofing materials such as tiles, corrugated sheets many times over because they are cheaper and offer a lot of variety. They offer wide choices in different profiles and colours and coatings. Various components such as ridge caps, eave trims, etc., that are required in pre-engineered buildings are readily available in the market.

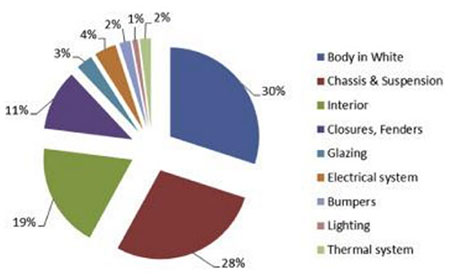

Automobile sector

(Image source)

About 50 to 55 % of automobile body components are made out of sheet metal. Sheet metal is the most preferred material in the auto sector as it offers required accuracy and forming technology which is essential and at cost-effective prices.

An example of share of sheet metal components in an automobile

Weight ratio of various vehicle components (Image source)

In an automobile, leaving aside the engine-related parts, the body, and its associated components have an important role in the weight of the vehicle. Nearly 50-60% percent of vehicle body components comprising of outer shell, chassis, and some interiors are all produced mainly using steel and aluminium.

These examples do not cover even a fraction of sheet metal applications. The applications are innumerable. The sheet metal market may be classified into steel, aluminum, and other metals such as tin, copper, and aluminum. Of these, steel accounts for the highest volume share of over 90%. On the other hand in terms of revenue aluminum accounts for the highest CGAR at about 9%.

4.1 Sheet metal market share

Durable (

Durable ( Cheap

Cheap Functional

Functional Economical

Economical Protective (

Protective ( Friendly

Friendly Aesthetic (

Aesthetic ( Economical (

Economical ( Different

Different Cost Effective (

Cost Effective ( Experimentative (

Experimentative ( Evocative (

Evocative ( Large (

Large ( Unbeatable (

Unbeatable ( Long and Short

Long and Short Modular (

Modular ( Professional

Professional Variety (

Variety ( (

( (

( (

( (

( (

( (

(