Traditional Kitchen Chopper

This timeless kitchen mate- Aadoli or Addoli as called in Konkani is a traditional kitchen chopper and grater. This is widely used in Southern regions of India to prepare vegetables for cooking and is easily available in the local markets. This is available in small to large sizes and can be customised as per one’s requirements too. The blade is the concentric black metal attached to the wooden plank and is extremely sharp. At the end of the blade is a round blade with a zig - zag grooves. This serves as a grater and is used to grate coconuts. One needs to sit on the wooden plank to chop and grate vegetables, coconuts etc.

Traditional kitchen chopper

[Image source]

A modern version of the same traditional design is presently available in the markets. Stainless steel and plastic are the materials used here instead of the traditional combination of wood and mild steel/ iron. Also in this modern version it is possible to fold the cutting blade back on to the base to avoid any accidents. This way it occupies less space and helps in easy storage of the chopper in the kitchen.

A modern vegetable chopper, with a rigid cutting blade.

[Image source]

2 in 1 Cut and wash chopping board with fixed blade

This is a modified design of the traditional vegetable chopper with a pivoted two way chopping blade which eliminates the risk of the curved, exposed cutting blade. This unique design sometimes has a vegetable cleaning drain basket along with a fixed chopping blade. At one end of the board is a 360-degree rotatable handle for easy cutting/shredding of all kinds of fruits/vegetables. The basket attached to the side is used to collect the chopped pieces. One can rinse and drain them because of the perforations present in the basket.

The chopping board is made using good quality food grade plastic and the blade is made of stainless steel.

Varieties of 2 in 1 chopping boards

Vegetable Slicers

A slicer is a very handy tool in kitchen to cut, slice and shred vegetables.

The preparation work prior to cooking becomes very easy with these slicers. They slice, dice, wedge and chop using different stainless steel serrated blades that can evenly slice a whole tomato without crushing it. The serrated blades cut through food items easily. The blades can be changed easily, so one can cut uniformly thick or thin slices of vegetables with this one device directly into a bowl.

These slicers also have a peeler attachment, a fruit huller attachment, different blade inserts for thin slices and a countertop -holder to position it on a kitchen counter. These are made using premium quality stainless steel and are stringently tested on various parameters to ensure high strength, superior finishing standards, durability, rust resistance and easy maintenance. The body or housing of these slicers is usually made of good quality food grade plastic. These tools are light in weight and designed to be easily and safely handled. Since they are made of plastic the cleaning and maintenance are usually simple to handle.

Indians have learned to adapt them well for their cutting requirements and style of cooking. Because of their consistent sizes while cutting vegetables, and also since large quantities of vegetables can be chopped faster, they are slowly replacing the traditional products that were previously used.

Shown below are some examples of multi function vegetable slicers with different attachments. These designs have evolved from some imported products.

A simple version of a vegetable slicer

A plastic holder with thin rods acts as a prong to hold the vegetable over the slicer. By moving this over the slicer in easy, smooth movements the vegetable gets sliced as can be seen below.

Electrical vegetable slicer

This type of slicer has a plunger which pushes the vegetable on to the slicing blade hence it is much safer to use. The vegetables are put in the processing chamber and pressed down with the safety plunger and when switched on, produces perfectly cut vegetables This is an ultra-safe automatic electrical mandolin-style slicer keeps fingers safe during the vegetable cutting.

The set includes a second, hidden safety switch that activates only when the plunger is in place and has three mandolin style blades for 1.5 mm slices, 3 mm slices and julienne strips.

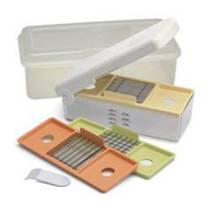

Box type vegetable slicer

Shown below is a box shaped vegetable slicer that is popular for its ultra-safe and automatic mandolin-style blades for slicing. It has a processing chamber into which all the slices or gratings will collect. It also has 3 types of mandolin style blades for producing 1.5mm thick slices, 3mm thick slices and julienne strips of vegetables or fruits. The parts are made of food grade, long lasting plastic and stainless steel for the blades.

Chopping Boards

A chopping board can also be called a cutting board. A kitchen would never be called as such without a chopping board. This is where one can prepare ingredients, such as spices, meat, and vegetables required for daily cooking. Kitchen cutting boards are often made of wood or plastic.

Today there are also chopping boards made of glass, steel, marble or corian, which are easier to clean than wooden or plastic ones, but tend to damage knives.

History

Women began using chopping boards centuries ago when they would chop the heads off of chicken and other birds, for cooking. They found it easier to get the knife to chop through the bone and flesh when there was a solid surface under what they were chopping. They would grab slabs of wood from the yard or elsewhere in the home to use for this purpose. Since cutting boards started out as solid wood, they continued along the same path for quite some time. The heavy wood makes an ideal surface for cutting and chopping, whether trying to cut through chicken bones or slice thin onions. The only issue with the wood is that often, chopping blocks are not treated and it is difficult to get them clean.

Now to purchase a new chopping board, whether in a kitchen specialty store or in an online shop, there is a huge variety of sizes, shapes and materials that the boards are made from. One can select different boards for different uses or simply have one to use for everything.

Materials

Wood

There are four common materials used in making chopping boards. Topping the list is wood. Wood usually has natural anti-septic properties, which means it can “disinfect” the chopping board immediately. It also doesn’t hold on to dirt and liquid, which will not only destroy the board immediately but also contaminate the food prepared. One of the downsides of wood is that it’s quite difficult to clean. Also, if it has a lot of cuts or cracks, it becomes a breeding ground for bacteria.

Hardwoods with tightly grained wood and small pores are best for wooden cutting boards. Good hardness and tight grain helps reduce scoring of the cutting surface and absorption of liquid and dirt into the surface. Teak's tight grains and natural coloration make it a highly attractive cutting board material, both for aesthetic and durability purposes. The natural oils in this tropical hardwood allow it to repel moisture, warping and microbes.

Wood boards need to be cared-for with mineral oil to avoid warping, and should not be left in puddles of liquid.

Besides hardwood, bamboo is also a well-known chopping board. Although technically a grass, laminated strips of bamboo also make an attractive and durable cutting board material. It’s preferred because it doesn’t allow bacteria to reproduce, and is also resilient and very durable.Wood has some advantages over plastic in that it is somewhat self healing; shallow cuts in the wood will close up on their own.

A wooden chopping board

[Image source]

Plastic

Plastic cutting boards are frequently used today for a variety of needs in the kitchen. Chopping vegetables on a heavy plastic surface seems to be more ideal than using a wooden board. The chopping board allows the cook to quickly and firmly chop fresh vegetables with a very sharp knife without injuring the kitchen counters tops. Plastic chopping boards can be quickly and easily cleaned and can even be put into the dishwasher when in a hurry.

While plastic is theoretically a more sanitary material than wood for cutting boards, testing has shown this may not be the case. The softer surface of plastic boards is scored by knives, and the resulting grooves and cuts in the surface harbour bacteria even after being well washed. However, unlike wood, plastic boards do allow rinsing with harsher cleaning chemicals such as bleach and other disinfectants without damage to the board or retention of the chemicals to later contaminate food.

Plastic boards are usually called PE Cutting boards, PE being a short form for polyethylene the material which the boards are made of.

A lot of design variations are available in these chopping boards. Some address the issue of flexibility, disposable options various forms, colours, sizes, etc.

Unsuitable materials for a chopping board

A knife edge is a delicate structure, and can easily be blunted by too abrasive a surface. Alternately, it can be chipped if used on a surface that is too hard. A good cutting board material must be soft, easy to clean, and non-abrasive, but not fragile to the point of being destroyed.

Hard cutting boards can, however, be used for food preparation tasks that do not require a sharp knife, like cutting cheese or making sandwiches.

Glass: While glass looks like an easy surface to keep clean, glass cutting boards can damage knives because of the high hardness of the material. Cutting on glass tends to dent, roll or even chip knife edges in a rapid manner. Additionally, if used for chopping instead of slicing, glass can shatter or chip itself, contaminating food. The tops of glass cutting boards are slippery, meaning the food can slip when one cuts food on them, leading to hand injuries. Alternately, washing can be difficult because of the possibility of dropping and shattering the glass.

Steel: Steel shares the advantages of the durability and ease of cleaning with glass, as well as the tendency to damage knives. Depending on the exact steel and heat treatment used, at best a steel cutting board will wear the edge on knives quickly, at worst chip, dent, or roll it like glass.

Marble: Most marble “cutting boards” are not actually intended for cutting, but for rolling dough or use as serving boards, such as for cheese. Aside from sharing the edge damaging properties of glass and steel, marble is also subject to chemical wear, and when exposed to some food acids such as tomato juice or vinegar, will slowly dissolve.

Choosing a chopping board

There’s just one thing to remember when choosing a large chopping board. It should never go beyond the size of the kitchen sink. This way, it would be easy for to clean it after use.

Decide on the purpose of the cutting board. Though these boards are generally used for, well, cutting, some of them have specific purposes. For example, those that have grooves in them are more ideal for cutting raw meat because the juices can be trapped in between these grooves.

It is safer, healthier and time saving to have separate chopping boards in a kitchen. To avoid cross-contamination, it’s best to maintain at least two chopping boards - one for meat and the other for fruits and vegetables. It would also make one more productive, since one need not wash the chopping board thoroughly before cutting the rest of the ingredients but simply use the other one.

Cleaning the chopping Board

It is important to clean the chopping board immediately after use. Otherwise, it could allow the multiplication of bacteria and other micro-organisms that can be harmful to one’s health and well-being.

The first step is to wash the cutting board with clean water and soap. One has to be careful about using cleaning solutions as some of the chopping boards don’t react well to them. A very dilute bleach solution is best for disinfecting cutting boards.

One should also not allow chopping boards to remain submerged in water for a long time, especially if it’s made of wood or if the water itself is dirty or looks contaminated.

To remove odours, especially in a wooden board it should be rinsed and then rubbed with coarse salt and let stand for several minutes. The board then can be wiped and then rinsed clean. This procedure will also smooth out minor imperfections in a wood board.

If the chopping board looks worn out, has a lot of dents or marks, and knives can already cut through it, this simply means that it’s a better and healthier option to replace it.