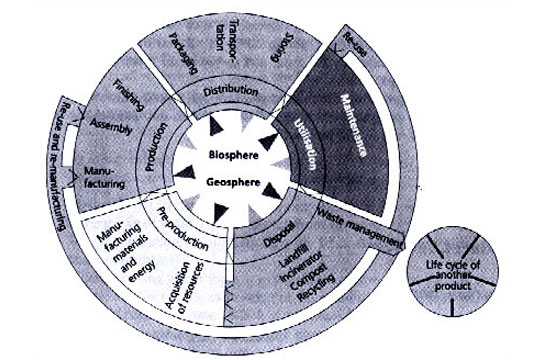

Product–system life-cycle:

Wheel showing phases from Prof. Ravi Mokashi’s presentation)

Source: Vezzoli, C., Manzini, E., (2008)

Product Life Cycle can usually be divided into the following phases:

• Pre-Production

• Production

• Distribution

• Use/Customer Interface

Pre-Production:

In the preproduction stage, necessary resources and semi-finished products are prepared as components of the manufacturing of the final product.

The sub-stages are:

• Identifying sources and acquisition of resources

• Delivery of resources to the production area

• Transformation of resources into raw materials or energy

The sources could be primary (primary resources) or secondary (recycled resources). Criteria for selection of low-impact materials are:

• Cleaner

• Renewable

• Have lower energy content

• Recycled

• Recyclable

• Have a positive social impact, (e.g., generate local income)

Production:

The three key stages of production are:

• Processing of materials

• Assembly

• Completion

The raw materials need to be conveyed to the machinery and processed into components after which they are assembled for the completion of the final product.

Characteristic for the optimisation of production techniques:

• Alternative techniques

• Fewer steps

• Lower and cleaner energy use

• Less waste

• Fewer and cleaner materials are used to support the production process

• Safety and cleanliness of workplace

Distribution:

Three fundamental stages that characterise distribution are:

• Packaging

• Transportation

• Storing

The final product is packaged in order to reach the end-user intact and functional; shipping is carried out by different means of transport either to an intermediate station or directly to the sphere of application. This stage entails not only energy consumption for transportation but also resource consumption to produce the means of transport as well as storage facilities.

Characteristics for the optimisation of distribution system:

• Less, cleaner, and reusable packaging

• Energy efficient transport mode

• Energy efficient logistics

• Involve local suppliers

Use/Customer interface:

Two fundamental stages that characterise utilisation are:

• Consumption

• Service

The utilisation or consumption of goods in most cases consumes resources and energy and leaves behind refuse and waste. Besides, they may require maintenance and servicing during its period of use.

Characteristics for reduction of impact during use:

• Lower energy use

• Cleaner energy source

• Fewer consumables required

• Cleaner consumables

• Health supporting and/or added social value

Characteristics for the optimisation of product lifetime

• Reliability and durability

• Easier maintenance and repair

• Modular product structure

• Classic design

• Strong product-user relationship

• Involve local maintenance and service systems

Product-System Life Extension Product System Life Extension strategies as described in the Life Cycle Design Guidance Manual: Environmental Requirements and the Product System (1993, January) US Environmental Protection Agency, Washington DC are as follows:

Appropriately Durable:

Durable items can withstand wear, stress and environmental degradation over long useful life.

A durable product continues to satisfy customer needs over an extended life. Impacts caused by products should be divided by estimated useful life. Such normalized figures allow designers to properly compare competing products.

Adaptable:

Adaptable designs either allow continual updating or they perform several different functions. Modular components allow single-function products to evolve and improve as needed.

Adaptability can extend the useful life of products that quickly become obsolete. to reduce overall environmental impacts, a sufficient portion of the existing product must usually remain after obsolete parts are replaced.

Reliable:

Reliability is a major aspect of quality. It measures the ability of a system to accomplish its design mission in the intended environment for a certain period of time. Unreliable products or processes, even if they are durable are often quickly retired.

Serviceable:

A serviceable system can be adjusted for optimum performance under controlled conditions. This capacity is retained over a specified life.

When designing serviceable products, the team should first determine who will provide service.

Maintainable:

The relative difficulty or time required to maintain a certain level of system performance determines whether that system can be practically maintained.

Repairable:

Repairability is determined by the feasibility of replacing dysfunctional parts and returning a system to operating condition.

Re-manufacturable:

Remanufacturing is an industrial process that restores worn products to lien-new condition. In a factory, a retired product is first completely disassembled. Its usable parts are then cleaned, refurbished, and put to inventory. Finally, a new product is reassembled from both old and new parts, creating a unit equal in performance and expected life to the original or a currently available alternative. In contrast, a repaired or rebuilt product usually retains its identity and only those parts that have failed or are badly worn are replaced.

Reusable:

Reuse is the additional use of an item after it is retired from a clearly defined duty. Reformulation is not reuse, however, repair, cleaning or refurbishing to maintain integrity may be done in transition from one use to the next. When applied to products, reuse is a purely comparative term. Products with no single use analogs are considered to be in service until discarded.

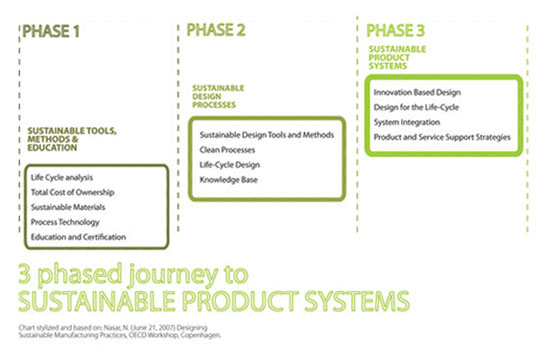

Three phased journey to Sustainable Product Systems.

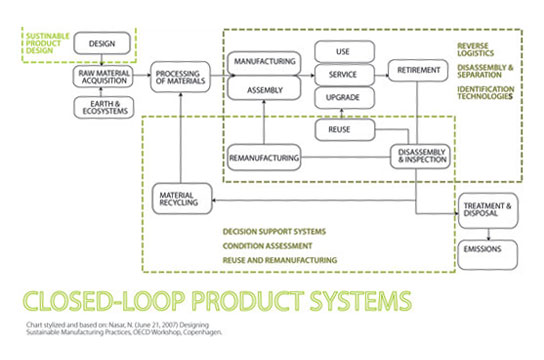

Closed loop Product Systems.

Image Source: Chart stylized and based on: Nasar, N. (June 21, 2007) Designing Sustainable Manufacturing Practices, OECD Workshop, Copenhagen.

Disposal:

At the time of disposal the product or its components can either be reused or recycled, composted or incinerated otherwise unused products are dumped into landfills or just dispersed into the environment.

Characteristics for the optimisation of end-of-life systems:

• Re-use of product

• Remanufacturing/refurbishing

• Recycling of materials

• Safer incineration

• Taking into consideration local (informal) collection/ recycling systems

The concept of life cycle is able to adapt a system vision over the products input-output during all phases, analyse and asses its environmental effect together with economic and social influences.