In plastics every finished product requires some kind of assembly for example many consumer electronic products like hair drier or kitchen appliances like mixer. The outer body parts of such products are manufactured separately and then finally assembled through mechanical fasteners, welding, snap fits etc.

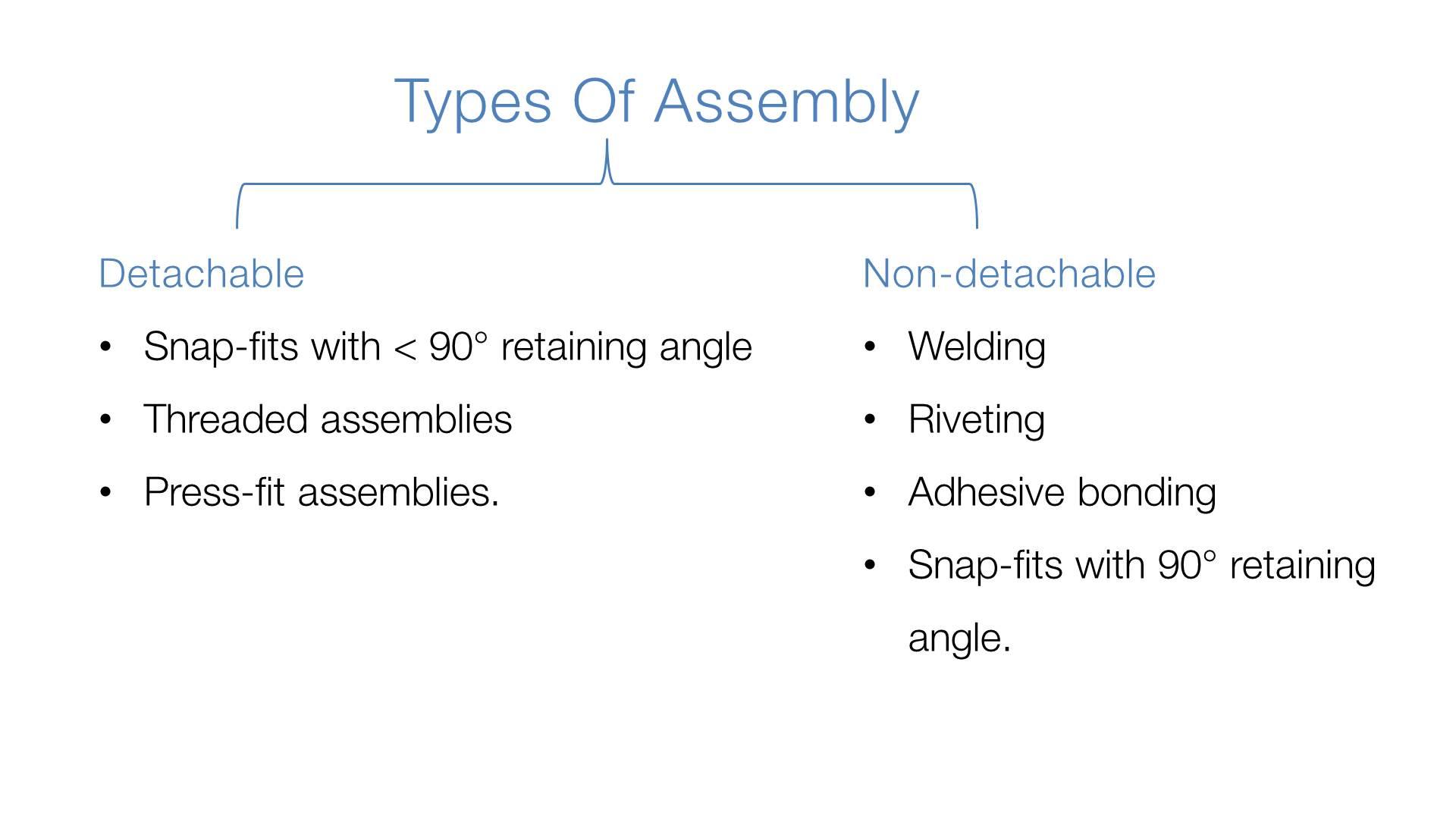

Assembly techniques for plastics depend upon the application of the product and the type of plastic used for the product. Broadly assembly techniques are classified under two categories detachable and non-detachable assemblies. Detachable assemblies are used in those parts which often needs to be separated like cap of a ball point pen, battery case etc. detachable assemblies includes special category of snap fits, threaded assemblies, hub assemblies and press fit assemblies. Non-detachable assemblies are kind of permanent assemblies and they cannot be separated easily. Non-detachable assemblies include welding, riveting, adhesive bonding, insert technology and special category of snap fits.