Design Resource

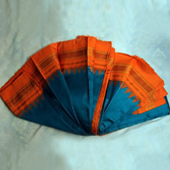

Ilkal Saree - Ilkal (Bagalkot), Karnataka

Traditional Styles of Sarees

by

Before the weaving of the Ilkal saree the cotton yarns are dyed into desired colours in the process of Cold water dyeing and Hot water Dyeing.

Cold Water Dyeing:

It is the process where the natural silk yarns or cotton yarns are separated from the bundle and firstly dipped into a soap solution then required dye is mixed into the soap solution and the yarns are further dipped into the dye solution to absorb the colour and are kept for some time. Then the yarns are taken out and with a rod the excess of water is squeezed out from the dyed yarn. The dyed yarns are kept under the sun to dry. The cold water dyeing is completed.

Hot Water Dyeing:

In this process liquid dye is mixed with water to from a thick solution where the bundle of yarn is soaked into the solution and taken out and are kept aside for further dyeing. Hot water is boiled in a vessel and dyed powder is added to the hot water to make a solution. The dyed yarns are further dipped into the boiling vessel and kept for two hours to absorb the colour. The dyed yarns are taken out of the vessel and the water is squeezed out and again the yarns are soaked in cold water and further squeezed and kept under the sun to dry.