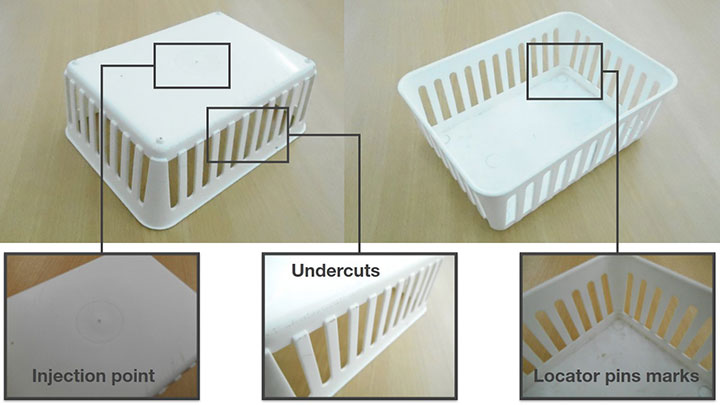

Any projection or hole which is perpendicular to Line of Draw creates obstruction in removal of piece such elements are called undercuts. Undercuts are formed by using split cavity molds or collapsible cores. Internal undercuts are molded by using two separate core pins but in this process flash must be controlled where the two core pins meet. For internal side wall undercut or holes offset pins are used. Undercuts are also formed by stripping the part from the mold but for such an operation mold must be designed to permit the necessary deflection. Slight undercut can be stripped from the tool.