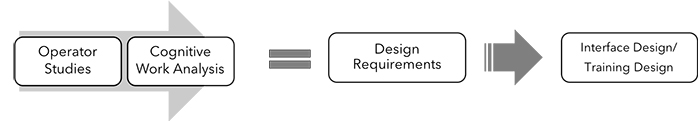

In the previous sections, we identified the challenges of interaction design in complex systems. Specifically, we noted the limitations of UCD for these systems as well as the need to understand the technology in experiential terms to support the mental models of operators. In this section, we will look into how we design interfaces for complex systems. Earlier, we had highlighted the need for a “joint optimization” of the human and technology. Therefore, one challenge is how to depict the constraints inherent in the technology so that the operators can act effectively on the system. HMI should ideally be designed in such a manner such that operators can act effectively on the system whenever required, in light of overall system safety. In order to achieve the design of an HMI, we will follow a few steps outlined below (we will only consider design in this tutorial and not evaluation, due to the intended scope). Further this section derives its steps from the following texts: Bennett & Flach (2011, 2013); Burns & Hajdukeiwicz (2004); Burns (2013). These texts are listed in the further reading section.

Step a - Understanding work domain, activity and processes

The first step of the HMI design process is to identify the boundaries of the problem under consideration. Identifying boundaries will help in understanding the nature of the system, tasks that operators will perform as well as have an eventual effect on the HMI design. Identifying the problem boundary is an iterative process. Once the designers start understanding the nature of the system and the work domain under consideration in more granular detail, they will be able to frame the problem boundaries for the particular system under consideration in a much more coherent manner. Typically, while framing the design problem, designers should not be including existing interfaces and interface elements at the outset. This is because the goal of the design/redesign is actually to introduce a new interface. Typically, we would want to include technological entities that the operator has to interact with (monitor, supervise or control) in order to do their work. Along with identifying the problem boundaries, a proper understanding of the operators’s activities, background capabilities and limitations is required. This can be achieved by field studies and information gathering methods such as interviews, observations, critical incident analysis, study of error logs and work-shift records. Along with the operators, there is a need for an understanding of technology in experiential terms. We turn to this issue in the next step.

Step b - Identifying design requirements and associated constraints

Once the insights and data are acquired in Step 1, we will use Step 2 to identify the design requirements. this step is covered by qualitatively modelling the requirements using an analysis framework called Cognitive Work Analysis (CWA). The CWA consists of five steps. the first step called the Abstraction Hierarchy (AH) is used here to elicit design requirements. The AH, and the corresponding CWA, are a part of a broader framework that has been developed by Rasmussen and colleagues (Rasmussen, 1986; Rasmussen, Pjetersen and Goodstein, 1994). The framework addresses various dimensions ranging from the work domain activities and operators.

In this tutorial, we are focussing on the AH which represents the work domain in experiential terms for developing the interface. Other steps are developed in greater detail by researchers such as Kim Vicente (1999) and will not be developed here in greater detail. We will be focussing on the first step that models the work domain under consideration. The modelling for eliciting out requirements for interface design can be achieved by this tool AH which is used for modelling the work domain qualitatively.

The AH was developed to understand the work domain or the technical environment that served as the basis of human decision making for operators. The AH has its roots in everyday practice in high-risk systems for understanding the mental models required by operators and maintainers in trouble-shooting technological equipment. Based on a few decades of research, Rasmussen identified a few generic categories of mental representations that operators use in understanding technological equipment. These categories were grouped together to form the AH. They range from functional purpose from one end to physical form at the other. These mental representations had a basis in the physical and technological dimension or the operator about the system. Therefore, it served as a basis of a combined mental model of the system. In this subsection, we will develop the AH in further detail to show how we extract information requirements for design.

How do we support mental models of the operators and use it for the design of technology using a structured design process.

In the AH, the figure shows a number of categories that are arranged in an ordered set. These categories can be understood as corresponding to different mental representations of the system that a person may use to understand the functioning of the system. These categories of representation connect the technical dimension of the system to the experiential basis of the operator. In order to demonstrate the various categories, we will use the example of an ink jet printer. Its complicated make-up will serve as an example to help us in understanding of the AH.

The first category involves functional purpose. In this level, the main issue is to capture the overall objectives of the system. The key ideas that are pertinent to this category are to capture generic descriptions that hold over the entire work domain under consideration. For example, the overall functional purpose of a printer is to print copies faster, use less ink and save money.

The second level labelled as abstract function addresses basic principles , law-based understanding and relationships that exist throughout the system. At this level, the focus of understanding is in terms of abstract principles. For example, in the case of the printer, we will think about stoichiometric relations when we calculate how much black ink is required to print 500 words on an A4 size sheet of paper. Therefore, the level of abstract functions allows for representing one category of mental models that the operators may employ while trouble-shooting.

The third level of generalized function represents the process involved in the technical functioning of the system. Oftentimes, in the process control systems, operators try to focus on the processes to gain an understanding of how the system is functioning. For example, in the printer, there are multiple physical processes relating to the paper moving through the printer as well as chemical processes related to the ink transfer on paper.

At the fourth level, of physical functions, the various components, objects and sub-assemblies are presented along with their capabilities. At this level, the representation is at the level that tends towards physical substructures and their associated functions. In our printer example, we will be considering components such as printer body, rollers, motors, among other entities and their associated functions.

Finally, at the level of physical form, we take into account the physical dimensions and attributes of the work domain or system under consideration. These include size, shape, color, appearance, location or general conditions of the various entities. In the printer example, we include many such attributes, such as dimensions of the ink bottles, paper thickness as well as other dimensions required for the representing the physical form dimensions of the work domain.

In the AH, these five categories are presented together as a unified structure. The upper layers tell us about the “reasons” of correct functioning of the work domain; whereas, the lower layers tell us about how possible malfunctions can propagate upwards and throughout the system. Along with the structuring of the hierarchy, the various levels are also connected to the levels above and below each other through links that are knows as means ends links. These links give us an insight into how the various categories or levels are interconnected to each other. If we focus on any one level, we answer the question “What?”. If we focus on the level above, we get an answer to the question “Why?” and when we focus on the level below, we get an answer to the question “how?”. This linkages of the “why-what-how” questions allows designers in structuring information and deciding on the priorities in the actual interface. This is discussed a bit later in this section. Up till now, we have described the abstraction hierarchy and its ability to represent a technological system in experiential terms derived from categories of operators’ cognitive activity and decision making in a variety of situations.

Levels of the abstraction hierarchy derived from a study of mental models.

Abstraction Hierarchy of a printer. Notice the why?-what?-how? links.

Based on these categories, we will derive a list of information requirements. These information requirements tell us about the various aspects we need to consider in our design and are derived in the process of filling up the abstraction hierarchy. The AH help us to derive these requirements in the form of variables that we put in at various levels of abstraction placed in the categories. From the abstraction hierarchy, these can be listed in terms of various categories to help the designer identify various requirements (see Figure below). These requirements will then be used in conjunction to develop graphic forms with the identified constraints and the means ends links in terms of the assigned priorities in the subsequent steps.

List of information requirements

Along with the information variable, the next step that will help in the design of interfaces is the identification of the constraints of the system as reflected through the variables. In order to extract constraints, we ask questions about the limits and possible interconnections. For example, in the case of the printer, we may ask at the level of the functional purpose: How many copies? How quickly? We ask similar questions of the other levels. E.g.

- Generalized function: maximum and minimum roller speed?

- Physical Form: size of rollers?, etc.

Identifying the constraints at various levels of the AH provides us with very specific insights about what is permissible for individual variables as well as at the level of multiple variables. These constraints along with the identified information variable serves as the basis of graphic forms and interface elements.

Step c - Identifying or developing graphic forms for displays

After the information requirements are addressed, our next step is to address the graphical forms of displays. Currently, this issue has been addressed by a number of very good design books that that include generic principles of information design and interface design elements. These generic design principles should be used judiciously with the principles of EID. Therefore, they will not be addressed here in greater detail and our focus will be on EID, in order to show how graphic forms could be developed to demonstrate the underlying constraints of the technological system that the operator can understand.

When we want to develop a new graphic form based on the information requirements, we ask questions such as the following: whether we need to depict one variable or a multitude of such variables? How are the variables related? How will the operator view and understand these variables in context? Are there existing graphic forms that the operators rely upon to make sense of their work?

In our design, we have to balance both the single variable constraints and the multi-variable constraints and depict them in the interface. For example, single variable constraints could be ink in one bottle. In this figure below, we are adding information that enriches the basic variables to demonstrate what can be achieved by manipulation of the variables. In other words, we are depicting the affordances of the variables that can be manipulated by the operator. In the figure, we have added a high cut-off for the deeper black color to be achieved; i.e., it shows that beyond this color, the color will be completely solid; whereas, below the lowest cut-off point the colour will be presented as faded. The two lines in the middle depict the current level of the ink in the cartridge.

Graphic forms showing single-variate constraints on activity (points beyond which deepest to faded black is represented.

Two graphic forms showing multi-variate constraints on activity of printing. the high quality (high quality preset) can be accommodated with a certain level of inks present; whereas, if the requisite amount of ink is not present then a lesser quality of print (low quality preset) could be obtained in the existing ink.

Along with single variable constraint, let us now consider a multi-variate constraint. For example, if you were printing a picture with different colors and your ink was limited. Then, the interface should ideally, help you to identify the current state as well as opportunities for further action. The figure of multi-variables show that given the amount of ink for blues and green, it is clear that a high quality print-out cannot be achieved. However, a low quality print-out is possible. Thus, multiple variables can be involved in depicting a constraint of the system to provide proper information.

Step d - Assigning priorities and structuring the display

In our final step, we establish clarity in the interface by structuring the various graphic forms. This structuring is helpful in providing the operator coherence and meaning. Designers’ use a number of principles (e.g. gestalt principles) to structure the interface elements and is often discussed in courses relating to 2D form and principles of information design. We will not go into those principles as they have been detailed in a number of design books and publications.

Based on the scope of our advanced primer, here we will discuss a crucial contributor from the AH — means ends links. Earlier, we had discussed the means ends (why-what-how) links that gave a generic insight into the structuring of the AH. One manner in which means-ends links work is by ensuring salience. Since operators may wish to see the functional purpose at the highest levels and may not move to the lower levels, we could improve the salience of the graphic. For example, one information variable can be made more salient as compared to others to depict its position in the AH; i.e., the broader levels of the aim of the work domain is addressed at the level of functional purpose and should be depicted at a more global level or maybe at the top corner of the interface to make it more salient.

Another strategy of improving design through the use of the means-ends links is to show the interconnections between variables that give information to the operator at any given point about “why-what-how” of the system’s functioning through the interface. The individual graphic forms must be interconnected to each other in such a manner that it should be clear for the operator that the variables of the level of physical function are connected to the processes in the level of generalized function. The key idea at this stage is to depict various interface elements in such a manner that it provides coherence and clarity to the operator to support their reasoning during normal as well as abnormal functioning.

EID starting from operator studies in context to interface design