This is a study for students to identify use of innovative materials and manufacturing processes in new product design. The class discussion helps to understand how boundaries of existing material and processes are broken to come up with innovative applications.

1. Danish Design firm PAPCoRN's Design:

The elegant, disposable dishes are made from Bioplast, a corn-based plastic that breaks down in a matter of months instead of centuries.

2. Product designed by Marcel van Galen:

A new over molding process that allows high-volume production of plastic parts bonded to fabric, leather, wood, metal or other materials.

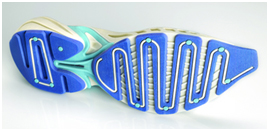

3. Realistic Reebok Shoe Sole Printed on 3D Printer:

Prototypes like this running shoe sole in high-definition plastics that define color to reflect original design data and to make sure models accurately communicate the design intent.

4. Designs of ART CENTER COLLEGE student - Ana Franco:

The piece is a environment friendly chair made of high quality environment friendly plastic.

5. Designs of ART CENTER COLLEGE student - Wen Yo Lu:

A combination stroller, child's car seat, and pogo stick, a product that has a long life span - specifically to extend the life of one product to save materials, cost, etc.

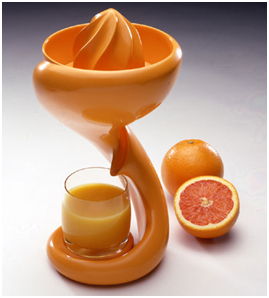

6. Designs of ART CENTER COLLEGE student - Paul Fu:

High quality food grade plastics are used in this product.

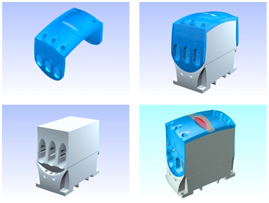

7. Design IDC – IIT Bombay:

Next generation contactor using Nylon 66 grade Dupont 74/33L for body and polycarbonate GE Valox 143 R for the Translucent cover.