Welding is a fusion process. The heat applied to the pieces to be joined will during will melt the metals to a fluidic state and fusion takes place. If the process is done correctly, the fused metal is as good as a homogeneous one. The strength of a weld is such that under tensile stress, rupture can only take place nearly at the ultimate tensile strength of the original metal. For instance, one single weld bead drop of about 6 mm diameter will easily hold more than 100 kg of weight in tension.

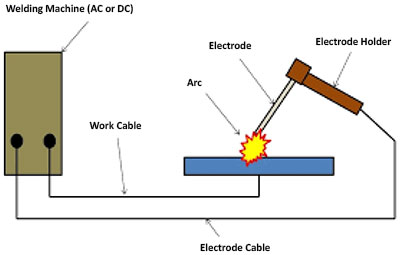

1. Arc Welding

(Image source)

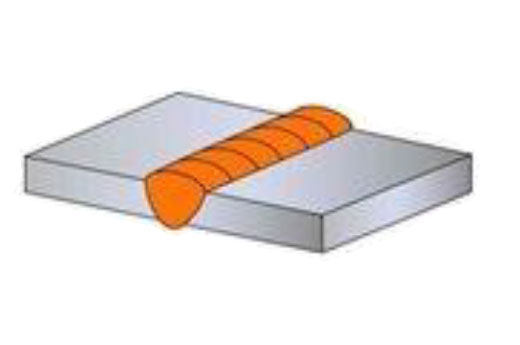

The basic arc welding which is also called Shielded Metal Arc Welding (SMAW) uses an electrode whose material is compatible with the base metals to be welded. This strikes an arc between the metal and the electrode to melt the metals to the fusion point. The core of the electrode also acts as the filler material. Oxidation of metal is the biggest problem in the welding process as oxidation causes lumps which weakens the joint. In arc welding, the electrode has a coating that generates gases during welding that offers protection against oxidation.

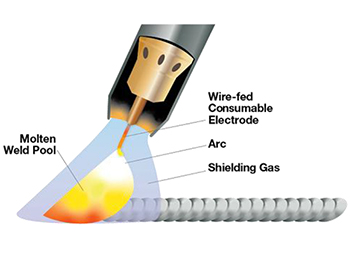

MIG welding process.

Gas Metal Arc Welding (GMAW) which is also known as MIG welding is a continuous wire welding process using a wire-fed electrode where a shielding gas around the electrode tip ensures protection to weld pool against oxidation. A variation of MIG welding is MAG ( Metal active gas welding). In MIG welding the shielding gas is an inert one such as Argon or Helium, meaning the gas does not participate in the fusion. In MAG welding the shielding gas is an active one such as CO2, meaning the gas actively participates in infusion. MIG welding is preferred welding for aluminium while MAG welding is preferred welding for steel. The shielding gas also impacts the behaviour of the weld pool, regarding the penetration and mechanical properties of the welded joint.

Typical MIG welding machine

Normal arc welding is not recommended to weld sheet metal parts as it is likely to burn the sheet because of high temperature besides allowing oxidation resulting in lumps and poor welds. Most often inert gas welding such as Co2 is adapted because of the gas shield at the weld point which protects the weld from oxidation. The thin wire electrode used helps in controlling the temperature better than in arc welding. Argon arc welding is used for stainless steel and aluminium sheets welding using stainless steel electrodes and aluminium alloy electrodes respectively.

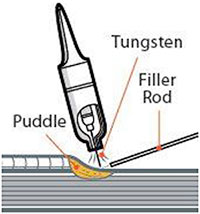

TIG Welding

TIG (Tungsten Inert Gas) welding involves a Tungsten electrode that supplies the current for welding. The filler rod is dipped into a molten puddle for the pieces to join. This is the most popular welding method for thin metals. TIG welding is especially used for nonferrous materials such as aluminium, copper, and bronze. TIG welding is more versatile in the sense that it can be used to weld many types of metals and alloys including steel.

TIG welding requires more skill than MIG welding because the operator has to use both hands while welding. TIG welding gives a cleaner weld joint appearance than MIG welding. It is however little more expensive.

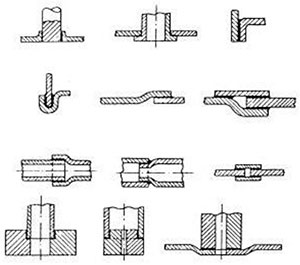

2. Types of Arc Welding

The primary types of welding the sheets together are “Butt”,”Lap”,”Tee”,”Corner”and “Edge” joint weldings.

Butt Joint

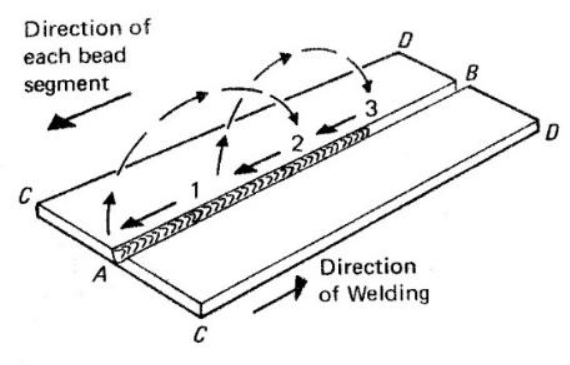

Skip and hop.

Skip and hop.

A butt joint is called when two workpieces are held together in the same plane and joined by a weld along their edges. In order to avoid distortions, welding is carried out in segments skipping and hopping along and in the opposite direction of the weld line. Metal sheets of over 3.00 thicknesses are generally employed for butt joints.

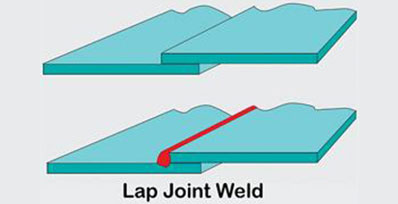

Lap Joint

A lap joint is called when a part of a sheet is made to rest on another sheet and joined by a weld along the edge and on the surface of the sheets. A Joggle joint is when one of the pieces is pressed along the edge to accommodate the thickness of another sheet.

Tee Joint

A T- joint is called when the edge of one workpiece meets the surface of another workpiece in a perpendicular manner with material on both sides of the edge. The weld which is carried out along the joint of the sheets perpendicular to each other is known as fillet weld.

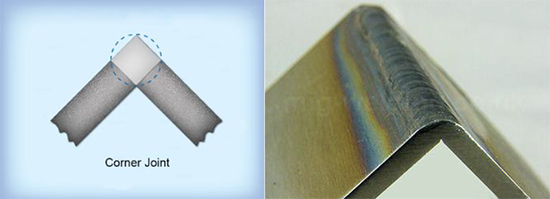

Corner Joint

(Image source)

When the edges of two pieces are perpendicular to each other and one piece’s edge aligns with the other piece’s surface, it is referred to as a corner joint. Common corner joints are edge to edge, flush corner, and half overlap, each with its own benefits.

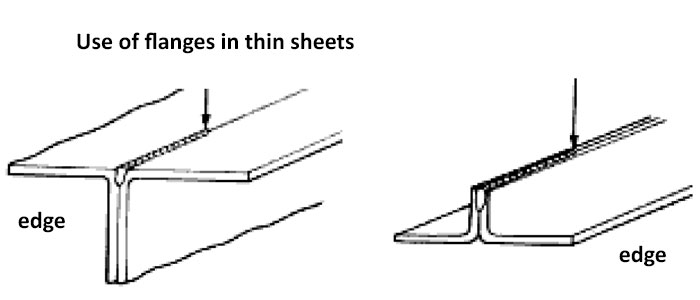

Edge Joint

An edge joint is when two edges of weld pieces are adjacent and in parallel planes with each other. The weld does not penetrate completely through the joint thickness so it should not be used in high stress or pressure situations. In thin sheet metals, a flange is created, and welding is done either at the edge of the flange or in between the flanges.

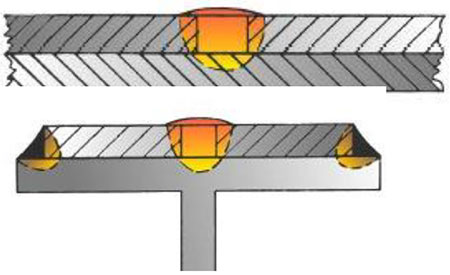

Plug Welding

(Image source)

A plug weld is used to join two pieces by welding through a hole in one of them to secure a bond and fill the hole with weld metal.

Joint Design in Sheet Metal

Butt joint weld for sheet metal is difficult and not advisable. If required edges may be folded a little and weld. A component should be designed in such a way as to increase metal thickness by way of a fold and carry out minimum possible welding. Consider if a tack weld may be sufficient instead of a full weld.

Folded sheet and joggled welding.

Folded sheet and joggled welding.

Defects in Welding

Porosity

(Image source)

Porosity occurs when gas bubbles are trapped within the weld. It is most common in normal arc welding. Proper temperature control and shielding against oxidation help prevent porosity.

Distortion

(Image source)

Steel sheet welding is a skilled process. Welding of sheets 0.5 to 2.00 mm thick generally involves high precision techniques. Warp and camber occur if proper care is not taken. Product design should keep in mind the distortions caused by the weld heat to the component and make allowances as required. When welding thin metal, the main objective is to avoid warping, burn-through, and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application.

To counter distortion, camber, and stresses due to heat.,skip welding is a technique employed. Heat dissipation is another method.

Heat Management

Skip welding. Skip and weld (Image source)

The normal method of the welding process is first to hold the job in position firmly and tack welds ( a spot of weld) at regular intervals applied along the desired weld length. After ascertaining the rightness of relative positions of pieces with respect to angles and straightness, full welding is carried out. Here Jigs and fixtures play an important role in holding the job in the position. Welding without holding the pice riding in place will lead to a very unacceptable end result. Even a spot of tack weld will make the job very rigid and distorted. It may be possible to knock off the weld bead and reweld but only at the cost of appearance.

The strength of the weld also depends upon the number of passes the welding torch makes along the line of welding. This in turn depends upon the thickness of the sheets as to how many passes are required.

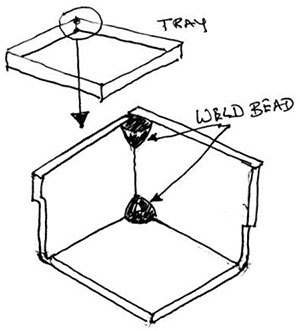

Corner Joints

Quite often corners of a sheet metal component such as a tray as shown need corner welding. If the corner finish is aesthetically important it is better to introduce a corner strap instead of direct edge welding.

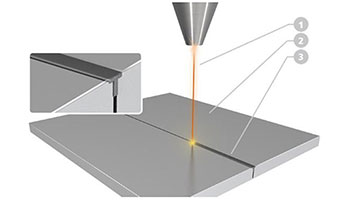

Laser Welding

Laser welding technology is a modern welding solution. A laser beam is highly focused and very intense. The impinged area of the beam receives energy ten times more than conventional arc welding. The beam can melt or evaporate all most any material. In butt welding, unlike other welding processes where weld material forms a bulge along with the electrode travel, laser welding creates a narrow and deep weld groove. This is because the surface of the metal where the laser beam touches evaporates because of the high-intensity heat.

Laser welding produces visibly smooth surfaces. It also reduces many post-weld operations such as grinding and sanding. The weld quality and productivity are much better in laser welding as compared to other conventional methods.

There are three types of laser welding which is in general use:

1. Fibre Lasers

Fibre Lasers are more versatile. The size of the materials to weld varies from very small to very thick. They are also relatively cheaper.

2. Nd: YAG Pulsed Lasers

These are a kind of doped synthetic crystal material lasers that are mainly used for spot welding. The size of the spot can be varied to suit particular applications such as deep spot or seam welding.

3. Continuous Wave Lasers

Continuous-wave lasers emit continuous laser beams with controlled heat input. These are ideal for high-speed welding because of the constant beam.

Though initial expenditure is more to install laser welding set up, it pays well as compared to MIG/MAG welding in large-scale production.

Stainless Steel Welding

Heat control is very important in SS welding. (Image source)

The main grades of stainless steel for welding purposes are 300 series and 200 series. The most popular austenitic stainless steel is grade 304. The filler material to be used for welding must be compatible with the base metal for a good weld joint. It is also important to monitor the temperature of both. The temperature of weld material and base material must be controlled properly to ensure good performance of the joint. While MIG, MAG welding is also used in welding stainless steel, TIG welding is the preferred choice.

In stainless steel, welding surface protection is of utmost importance because stainless steel is very sensitive to the presence of carbon. The presence of co2 gas or residues of carbon on the work table or tools can react adversely with stainless steel under welding. Also, stainless steel is very unforgiving in hiding mistakes. Every scratch, discoloration, and blemishes are more pronounced than in MIG/MAG welding.

Colours in the weld bead mean oxide formation which affects corrosion resistance. The colours vary from chrome to gold to deep purple. The darker the colour more is the oxidation. Oxidation on the surface is acceptable but below the surface, porosity occurs.

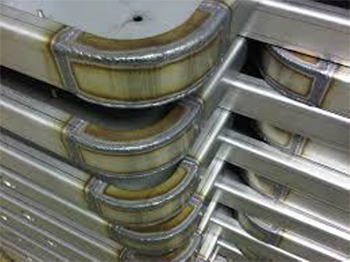

Aluminium Welding

(Image source)

Aluminium has always a coat of oxide present on the surface which acts as a barrier for quality welds. This oxide melts at a much higher temperature than aluminium itself. It is, therefore necessary to remove the oxide coat either by chemical or mechanical means. Aluminium has high thermal conductivity and a low melting point. While this is useful for quick solidification of the weld, it is advisable to dissipate the heat quickly. The solidified weld bead’s volume is much lower than the volume of the molten weld bead, therefore distorting during the time of shrinking. It is also important that the welding is carried out at a faster rate and with some heat dissipation methods. The most popular method adapted in aluminium welding is gas tungsten arc welding or TIG welding followed by gas metal arc welding or MIG welding.

Tip

While fabricating components such as panels and trays explore if inside corners can be welded rather than outside corners. This will eliminate grinding and sanding on the outside to ensure a clean appearance.

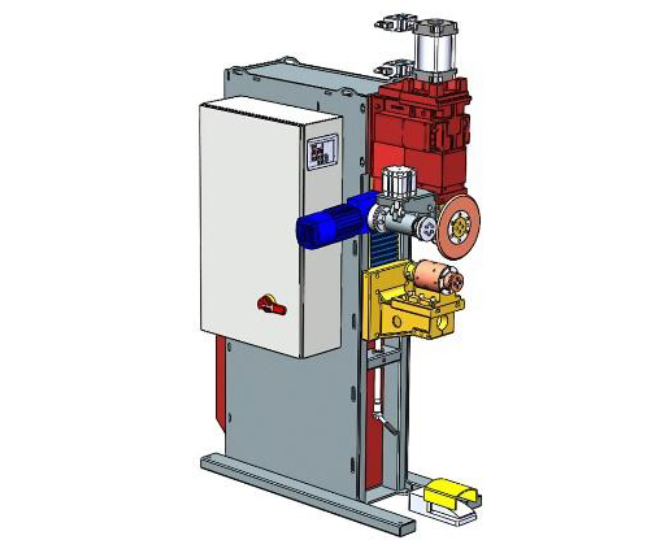

3. Resistance Welding

Resistance welding is a metal fusion welding technique where the materials to be joined are heated by electrical resistance and fused together with some pressure. Resistance welding is employed to join parts of steel, aluminium copper, bronze, and the like where electrical conduction is ensured. Spot welding, seam welding, projection welding processes are all form part of resistance welding techniques.

Spot Welding

Spot welding is when a spot of a weld is created between two sheet metal parts by resistance welding to fuse together the parts.

Extensive use of spot welding in automobile bodies.

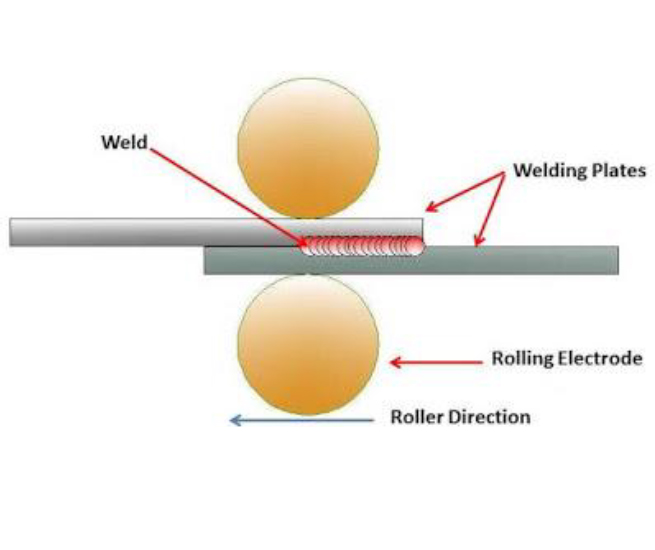

Extensive use of spot welding in automobile bodies.Seam Welding

Pipe formation by seam welding. (Image source)

Pipe formation by seam welding. (Image source)

Seam welding may be inferred as continuous spot welding in which a roller-type electrode is used to flow current through workpieces for continuous welding. A high ampere current is made to pass through the set of rollers which moves the sheets forward to be joined. This will create a continuous weld joint that can be air-tight.

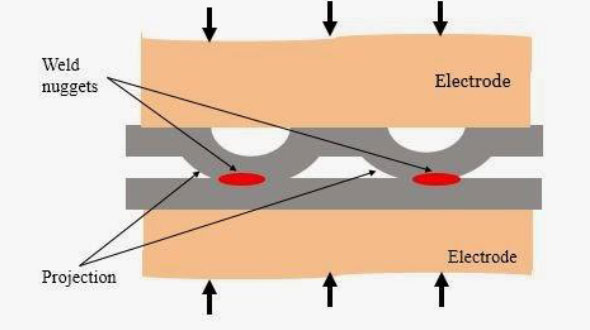

Projection Welding

The nuts on the wheel hub are projection welded.

The nuts on the wheel hub are projection welded.

Projection welding process is a type of resistance welding. Projection welding requires studs to be placed on the metals to be welded. The shape of such studs can be button types, cone types, or spherical types depending upon the thickness of the materials to be fused.‘

4. Brazing

Suitable Joint Designs for Brazing

Image courtesy: Handbook of Brazing and Soldering

(Image source)

Like in welding brazing uses a filler rod to apply molten material onto work-pieces. Brazing differs from welding in that the temperature is far lower allowing better dimensional control. Brazing does not melt the base metal. The important aspect of brazing is the joint design. Many types of joint designs are possible to enable different choices.

(

( (

( (

( Butt weld in progress.

Butt weld in progress. (

( (

( T Butt welding in a structural frame. (

T Butt welding in a structural frame. ( (

( (

( Butt welding of thin sheets.

Butt welding of thin sheets. (

( (

( (

( Direct corner edge welding.

Direct corner edge welding. Corner strap welding.

Corner strap welding. Laser Beam Laser weld quality.

Laser Beam Laser weld quality. Work Piece.

Work Piece. Weld Seam.

Weld Seam. Welding process.

Welding process. Floor standing Spot Welder.

Floor standing Spot Welder. Portable Spot welder.

Portable Spot welder. Resistance welded automobile door.

Resistance welded automobile door. Seam Welder.

Seam Welder. Seam welding of sheets.

Seam welding of sheets. Seam welded Drums.

Seam welded Drums. Seam welded tube.

Seam welded tube. Projection welding process.

Projection welding process. Brazing does not percolate into metal.

Brazing does not percolate into metal. A cleanly finished brazed component.

A cleanly finished brazed component.