Ambadi, globally known as Roselle (scientific name: Hibiscus sabdarifa), is a nutritional herb with various health and economic benefits stemming from the processing of its various parts. Over the past few years, the importance of Indian rosehip has re-emerged as a nutritional and medicinal herb. Global demands have skyrocketed for its healthy Hibiscus tea. It is envisioned that Indian rosella reaches a higher economic potential to match that of Malaysia, China, and Africa. The current bottleneck lies in optimising the separation process so that more produce can be made from the 10-day annual cultivation season. Hence, this project aims at bringing in a design intervention for enhancing production while exploring MSME and SHG style set ups to enterprise the crop and bring benefit to the farmer and associated channels at large.

The plant’s morphology and vernacular nomenclature were first observed, along with gathering all available information about the dimensions of the varieties under cultivation. Through the RuTAG team and the project guide’s network in Vidharbha region, two enterprises were found: one was an institute for village initiatives, and the other was an entrepreneur who has India’s first FSSAI licence for Ambadi Tea. The two economic models were thoroughly studied for their approaches to labour, logistics, and quality. Desk research about Roselle’s development in Florida, Sudan, Kenya, and Malaysia was done, along with understanding the basics of food post-processing. Two commercial retailers from e-commerce websites were also contacted to seek bottlenecks for the industry in general.

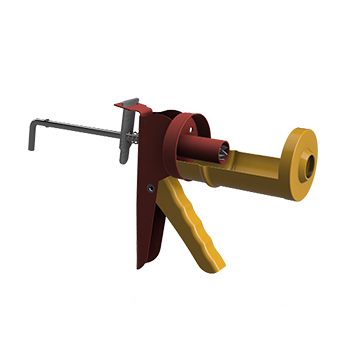

The task at hand was to reduce the drudgery in the calyx removal process of Ambadi, and initial ideations, including sketches and mockups, were done much before the harvesting period so as to get primary feedback from stakeholders while doing an initial field visit. This helped us have very involved conversations with the enterprise heads, and the modifiable nature of the mockups helped us quickly iterate based on feedback.