Design Resource

Silk Saree Weaving - Arani

Saree Weaving -Tamil Nadu

by

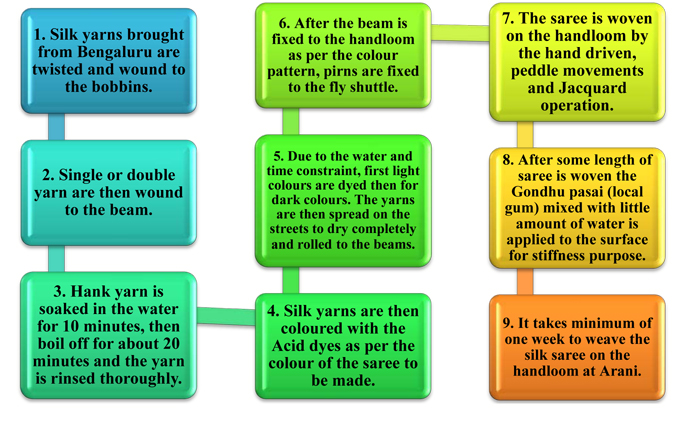

Silk yarns brought from Bengaluru of the Karnataka state are twisted and winded at Arani as per the requirement of the single and the double yarns to the bobbins. The silk yarns are then wound to the beams and then taken for the boil off and the colouring process.

The hank of silk is boiled in the soap solution for the boil off process and dried completely. It is then dipped in water and immersed in the dye solution which is boiled with acid dyes in the brass vessel by providing heat by the firewood.

Depending on the pallu and body part of the saree with respective colors it is dyed by tieing those portions with plastic covers and rubber tubes respectively and coloured. The yarns are then spread on the streets to be dried completely and wound to the beams and the pirns for the weaving purpose.

As the beams and the pirns are loaded to the loom and the shuttle. It is then run by the hand driven and the peddle movements by the hands and leg movements of the weaver. A cloth bag with sand balances the lifting movement of the yarns. After certain length of the saree is woven it is applied with the Gondhu pasai (local gum mixed with water) to give the stiffness to the saree woven. Therefore there is no need for any further finishing treatment for these sarees. These are light weight with various traditional designs with zari and silk yarns.