The loin loom or the back strap loom is an ingeniously simple device. Most of the parts are made from bamboo and wood. It is called loin loom or back strap loom because the warp yarns are stretched between two parallel bamboos, and the bamboo at one end is fixed to a wooden stick or branch driven into the ground, and the bamboo at the other end is held firm by means of a strap worn around the lower back of the woman weaver. The weaver regulates the tension by bending forward and backward. If she bends forward the warp yarns become loose and if she bends backward the warp comes into tension. The loom is made of several bamboo sticks around which a continuous warp is wound. The entire length of the warp is stretched out and not wound over a beam as in frame looms. The threads of the continuous warp are separated into two layers which lie one above the other. One set of warp threads is kept separate from the other with the help of a "shed stick" and "yarn heddles".

A bamboo of fairly large diameter is placed over every alternate thread. The threads from under the shed stick are strung with yarn heddles, while the threads which pass over the shed sticks are left free. Weaving is the interlacing of two sets of thread at right angles to one another. This interlacing takes place because of a "shed" and the simplest weave require at least two different sheds. In the loin loom one shed is formed when the weaver bends forward to loosen the warp threads. As the warp is loose she is able to lift the yarn heddles mounted on the "heddles stick", thereby rising every alternate warp thread. A wooden beater is inserted into the gap and made to stand on its edge to form the shed. Having formed the shed the weaver leans back to bring the warp into tension and insert the weave. This is followed by moving the heddle stick closer to the shed stick, whereby the warp threads coming from the over the shed stick remain above the warp threads strung by the yarn heddles. Into this gap the beater is inserted forming a shed just like before and the second weave is inserted.

As the weaving progress the weaver pulls the woven fabric into a clockwise direction thereby bringing the unwoven warp forward for weaving .in the Northeastern region there are two methods for making the warp. In the method used by the Naga, the warm is made on a horizontal frame and then stretched to its full length. Then the weaver proceeds to transfer the lease onto the bamboo shed stick and to string the warp threads with yarn heddles. The other method of making the warp entails making the entire loom itself. The weaver sits on the floor and is assisted by another woman who travels back and forth with a bobbin of yarn, helping to build the entire length and width of the warp. The weaver separates the thread of the top layer from the bottom layer by placing them alternating under and over the shed stick. The threads from under the shed stick are then strung with yarn heddles. In this method the warp, the shed and the yarn heddles are

made thread by thread.

The warps are generally narrow, not wider than 50-60cm in width. This loom does not have a reed and the weaver varies the density of the fabric by spacing the threads closer or further apart while making the yarn heddles. A block of wood or stone is used a foot support, which helps the weaver to bend backward. When the weaver has finished weaving she winds the loom into a bundle. Loin loom weaving is quite strenuous and compared to weaving on a frame loom, one cannot weave for as long a period of time.

In the Northeastern region, loin loom weaving is done by women only. Weaving is seasonal for those women who work in the jhum cultivation. The women weave fabrics primarily for their families and themselves. In Nagaland, one comes across many occasion where women produce shawls and sarongs on their loin loom for the purpose of sale.

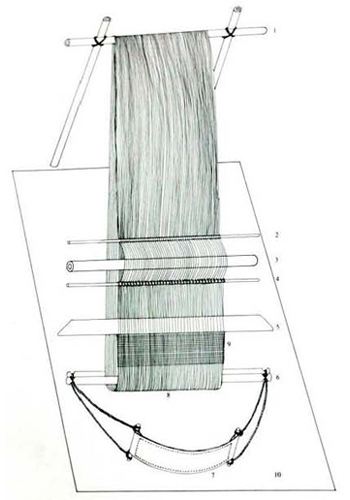

Parts of a Loin Loom:

1. Bamboo which serves the same purpose as the warp bream in a horizontal frame loom.

2. Thin bamboo rod which acts as a lease rod.

3. Bamboo shed stick.

4. Thin bamboo heddle stick which holds the yarn heddles.

5. Wooden beater.

6. Wooden rods which serve the same purpose as the cloth bean in a horizontal frame loom.

7. Leather back strap.

8. The continuous warp.

9. The woven fabric.

10. Mat spread on the floor on which the weaver sits.

(Illustration: textile and bamboo crafts of the Northeastern region - Aditi Shirali,1983)

1. Bamboo which serves the same purpose as the warp bream in a horizontal frame loom.

2. Thin bamboo rod which acts as a lease rod.

3. Bamboo shed stick.

4. Thin bamboo heddle stick which holds the yarn heddles.

5. Wooden beater.

6. Wooden rods which serve the same purpose as the cloth bean in a horizontal frame loom.

7. Leather back strap.

8. The continuous warp.

9. The woven fabric.

10. Mat spread on the floor on which the weaver sits.

(Illustration: textile and bamboo crafts of the Northeastern region - Aditi Shirali,1983)

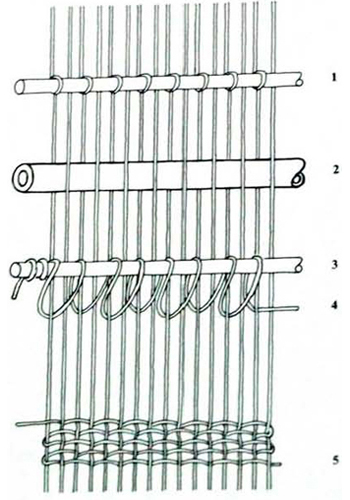

The warp threads with yarn heddles:

Detail showing the manner in which the warp threads are strung with yarn heddles. Every alternate warp thread is wound around the lease rod and the yarn used to form the heddle is strung through this set of alternate threads the first shed of the plain weave is formed by threads which pass over the bamboo shed stick and the alternate warp threads strung by the yarn heddles remain below as they passs under the shed stick. The weft is inserted into this shed.

1. Lease rod.

2. Bamboo shed stick.

3. Heddle rod.

4. Yarn to make the heddle.

5. weft.

(Illustration: textile and bamboo crafts of the Northeastern region - Aditi Shirali,1983)

Detail showing the manner in which the warp threads are strung with yarn heddles. Every alternate warp thread is wound around the lease rod and the yarn used to form the heddle is strung through this set of alternate threads the first shed of the plain weave is formed by threads which pass over the bamboo shed stick and the alternate warp threads strung by the yarn heddles remain below as they passs under the shed stick. The weft is inserted into this shed.

1. Lease rod.

2. Bamboo shed stick.

3. Heddle rod.

4. Yarn to make the heddle.

5. weft.

(Illustration: textile and bamboo crafts of the Northeastern region - Aditi Shirali,1983)

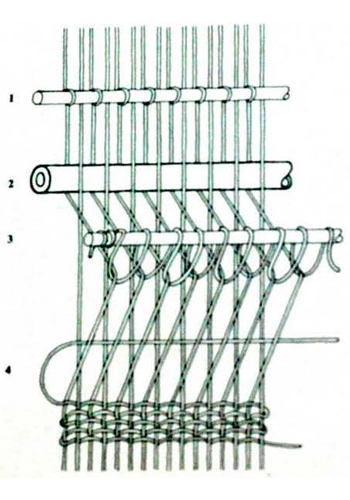

Second shed of the plain weave:

The second shed of the plain weave is formed by lifting the warp threads strung by the yarn heddles. The weft inserted into this shed lies above the warp threads which wereraised in the previous pick shown in Fig.

(Illustration: textile and bamboo crafts of the Northeastern region - Aditi Shirali,1983)

The second shed of the plain weave is formed by lifting the warp threads strung by the yarn heddles. The weft inserted into this shed lies above the warp threads which wereraised in the previous pick shown in Fig.

(Illustration: textile and bamboo crafts of the Northeastern region - Aditi Shirali,1983)

Preparing the warp (photo: U rütsonyie mu u nyaürako miarhi da

__ An angami cultural photo album by Angami Women Organisation, 2007).

Traditional method of weaving using loin loom. (photo: U rutsonyie mu u nyaurako miarhi da

__ An angami cultural photo album by Angami Women Organisation, 2007)