Design Resource

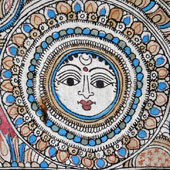

Kalamkari Painting

The Art of Fabric Painting using Natural Links

by

The tools and raw materials used for the production of traditional Kalamkari printing are basic handmade and natural materials. Kalam-bamboo pen is the most important tool used in printing process. This is made of bamboo reed. A cotton cloth is rolled over the reed and it is tangled by a cotton thread. Two types of kalams are prepared for outlining and color filling processes. The cotton cloth used for the fabric printing is locally called as Gaada. Vegetable dye stuffs like Myrobalan flower (Karakapuvvu locally) and Myrobalan bud (Karakapinde locally) used to make the black dye permanent. Chavalakodi and suruduchekka are the two types of roots which are procured from local forest areas are grounded into powder to obtain red color. Pomegranate skin is used to obtain light yellow color. Alum is the mordant used in dyeing process. Khatta-is the substance boiled to obtain lighter red color.

Kasim kaaram-Iron black color solution prepared using rusted iron filings, cane jaggery and palm jaggery. These materials are dissolved in water in a closed earthen pot and allowed for fermentation. After 10 days the solution is filtered and the iron filings are taken out. The prepared Kasim kaaram is used for drawing outlines and to fill black color. The tamarind stems are burned and made into charcoal. This charcoal is used for initial sketching. The buffalo milk is used to treat the cloth which helps to avoid color spreading.