Design Resource

Bandhani Work - Kutch, Gujarat

Traditional Tie and Dye Technique

by

Prof. Bibhudutta Baral and Amulya S.

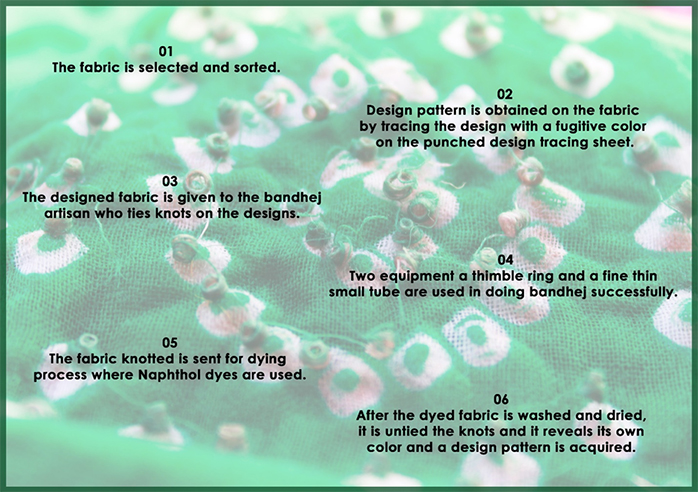

The fabric is selected and sorted. The fabric is folded horizontally half and straight stitch or hemming is made at the ends. The design pattern on the tracing butter sheet is traced with the fugitive blue color, which is in continues design pattern where only half a fabric is marked and automatically the other half gets the design. The shoe brush is used in brushing the fugitive color over the tracing sheet to acquire the design on the fabric. Previously the designs were marked with imprints of wooden blocks and threads. In tracing butter sheet the design is drawn and it is punched in a manner with the tiny dots in a sequence which produces the design once the color is brushed on the sheet. After the fugitive color has dried the fabric is sent to the Bandhej artisan who is usually a woman who ties the knots in her leisure time.

Tying Process:

The water resistible threads like nylon, synthetic are used in order to avoid the dye color absorbent into the fabric by tying the knots. It takes around a week to finish tying knots for one veil or a scarf. There are several types of designs like Scatter dots, Circum Bandhej and Barthi Bandhej. Scatter dots are the general and common designs made in amid of the fabric which brings a beautiful pattern of dots spread across the borders of the cloth. Circum Bandhej is a continues flow of designs and Barthi bandhej is a lot of knots made closure to each other in order to obtain intricate designs. The pointed thimble ring is worn on the finger ring of the left hand which helps in protruding the fabric which later is winded with a thread tightly obtaining a knot. With the help of a fine thin small tube locally called Nalli or bhungri is held with right hand where the thread has passed through that tube which, in later it is winded towards the protruded cloth and knotted. Apart from this there are several traditional patterns in Bandhej like Dungar Shahi - the mountain form, Chaubasi - knots in group of four, Tikunthi – knots in group of three, Satbandi – in groups of seven, Ekdali – a simple dot, Boond – a small dot with a dark centre, Kodi – a tear drop shaped like, Leheriya – wavy patterns and Laddu Jalebi – the design is in the swirling form. After completely tying the knots on the design, the fabric is thoroughly washed to remove the fugitive color print and it is sent for dying process.

Dying Process:

In dying process there are several techniques in dying the Bandhani work like direct dyes, Vat dyes, Naphthol dyes and Acid dyes. Acid dyes are more efficient and often used for silk material whereas for cotton naphthol dyes and vat dyes are used. The knotted fabric is dipped in naphthol solution with Salt, Formaldehyde, and caustic soda for about five minutes and then it is rinsed with clean water, squeezed and dried. After the fabric is semi dried it is dipped into diazotization base component where the fabric obtains its required color. Which in later is rinsed, washed and dried with clean water to remove the extra dye from the fabric.

After the dying is complete the fabric is washed in clean water and machine dried. And it is hang for drying in air. Once the fabric is completely dry the knots are removed by pulling the fabric tightly which brings the white patches made out of tying. The tied knots of fabric help in avoiding the color to enter thus it retains its own color. The designs obtained can come in multi colors as per the requirement. Chemical dyes are more preferable because the color is acquired bright and colorful.

Flow Chart: