Drawings Download......

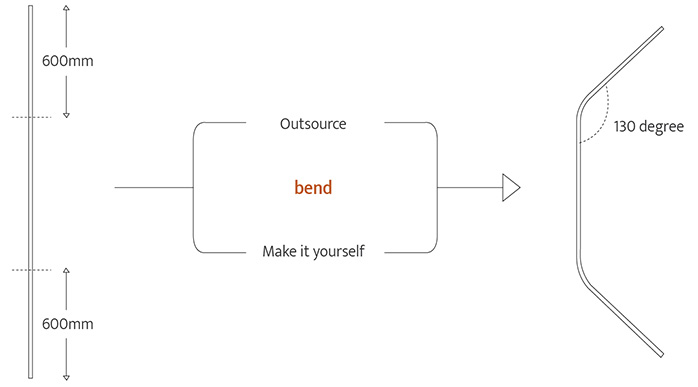

Step 1: Bend the structural pipe from both the ends.

Outsource: Get it done by a local manufacturer.

Contacts of local pipe bending vendors.

Make it yourself: Use a pipe bending machine/tool.

Links to videos for pipe bending process.

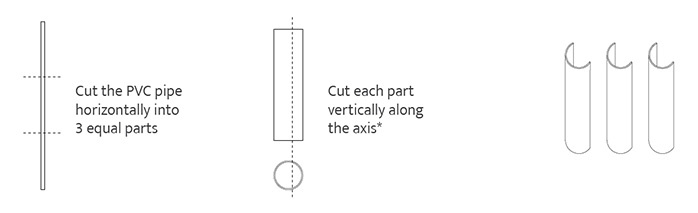

Step 2: Cut the PVC pipe for the central joinery.

*The vertical cut should be more than half so that it snaps to the structural pipe.

Outsource: Get it done by a local manufacturer.

Make it yourself: Use a bench vise to hold the PVC pipe and cut with a hacksaw. Or you can use a sanding machine shown in the video.

Links to videos for PVC pipe cutting process.

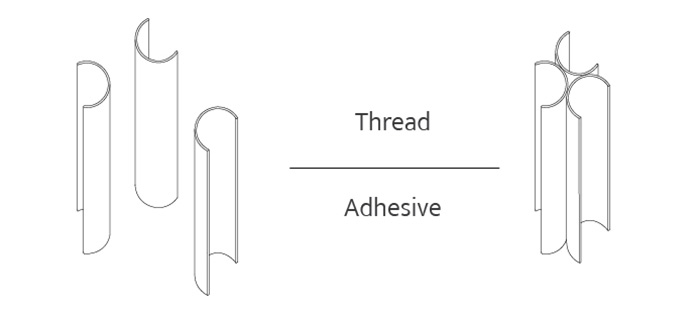

Step 3: Stick the cut PVC pipes.

Place the three PVC pipes as shown above and place thread strands in between. Sip adhesive (Fevi Kwik) through the thread strands. Hold the pipes firmly till the adhesive dries.

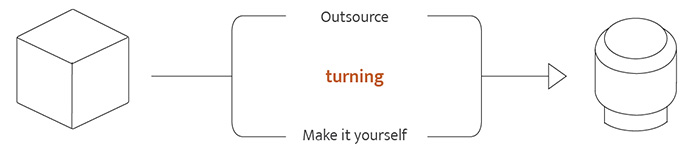

Step 4: Make the wooden stopper in lathe machine.

Outsource: Get it done by a local manufacturer.

Make it yourself: Make it using hand tools like saw, chisel and sanding equipments.

Contacts of vendors for lathe machine.

Links to videos for lathe turning.

Step 5: Paint all the components.

Step 6: Assemble it in just 2 mins!