Design Resource

Candle Making - Bengaluru, Karnataka

Handmade Candle

by

Prof. Bibhudutta Baraland Rakshitha

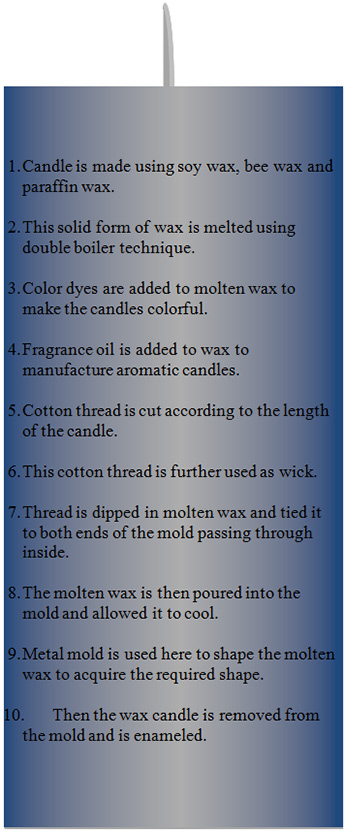

Candles are made using wax. Making of these scented candles depend on selecting the wax for their product. Usually paraffin wax is used for making these candles. Some manufactures use soy wax and bee wax along with paraffin wax for the better quality. Initially a solid form of wax is melted in a unique technique called double boiler method. This method is followed to melt the wax as it prevents the wax from catching flame and also controls the temperature. In the boiler that is used for melting the wax, 0.5/4th of water is poured into the boiler and the blocks of wax are allowed to melt at 50-55 degree Celsius. To make the vertically lengthy candles, wax is melt at 59 degree Celsius. To improve the long lasting potency of the candles a hardening agent is added to wax. Desired candle dyes are also added to molten wax to make vividly colorful candles. Fragrance oil of about 15 to 30 ml is added to maximum 45kgs of wax to prepare beautifully aromatic candles. Different types of fragrances used are chocolate, bayberry, sandalwood, jasmine, ocean mist and few others.

After the wax is melted it is shaped to required design using metal molds (made from Aluminium material). Before pouring the molten wax to the mold, a required length of cotton thread is cut according to the candle size. This cotton thread is further used as the wick to light the candle. The chosen cotton thread is then dipped in molten wax and tied it to both the ends of the mold passing through the inner side (in centre). Then the molten wax is poured into the mold and allowed it to cool. Once the wax candle is completely cooled, it is removed from the mold and the excess of wax is trimmed using the knife. These candles are painted using oil based enamels.

There are few candles that are called container candles. They are usually composed in a glass or plastic containers of various shapes. The process of making these candles vary slightly when compared to the vertically lengthy (standing) candles. Here the wick is placed in the candle container at the appropriate place by the help of a metal wick holder. Further molten wax is poured to the container. Few such candles are stored in small aluminum container as well. These container candles are hand carved and dipped in different colors of molten wax. This process continues until the required layers are formed on the candle. When the wax is still hot, the artisan cuts the layer and forms the design. This cutting and designing of wax is only carried on while the wax is hot before the wax gets cooled and dried up. Once the candles are prepared, they are dipped in acrylic solution to polish the product. These products are further decorated with few more decorative accessories to make them look all the more attractive.

Flow Chart: