Design Resource

Cane Furniture - Sandur, Karnataka

Craft of Making Cane Products

by

Prof. Bibhudutta Baral, Divyadarshan C. S. and Manmi Dutta

The cane products have established a significant position in the sector of handicrafts. Cane being an eco-friendly product is cultivated in abundance in few of the India states. Over the years the rural people has developed the art and skill of weaving furniture’s with cane. Cane is mostly used as a substitute for wood. Cane products are durable and have a high life with least preservation with their own elegance and style. The unending demand of cane has resulted in many artistic works of cane. Cane objects are also used as interior beautification of houses and commercial places. In the Sandur Kushala kala Kendra craftsmen are divided into several groups according to the various crafts practiced in the Kendra.

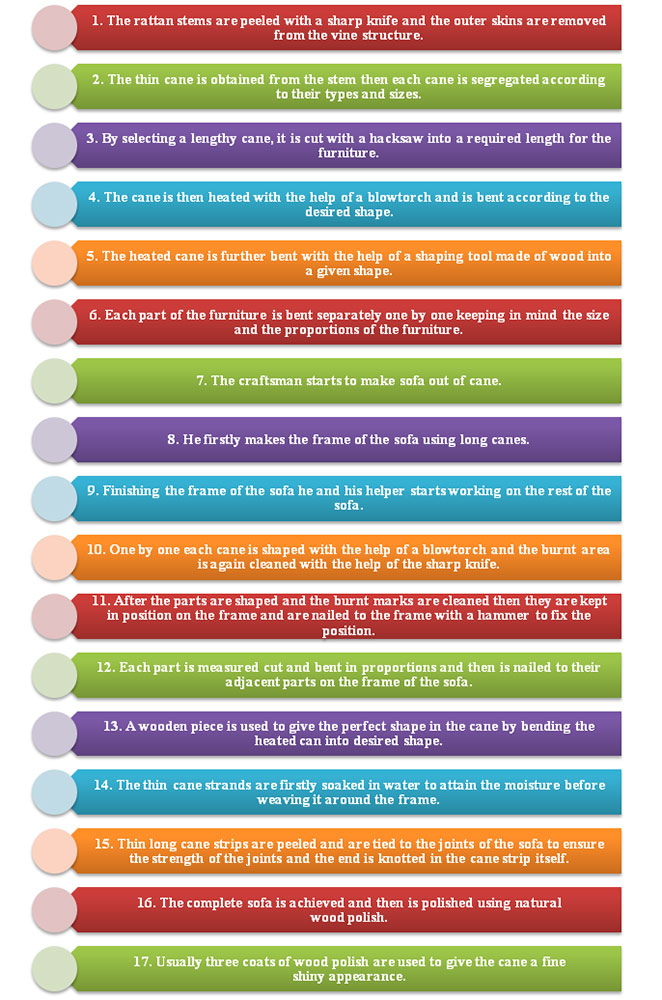

Sandur Kushala kala Kendra purchases all the rattan stems in Lorries in huge amount mostly from the Dandeli forest of Karnataka, where cane is been cultivated in large quantity for the purpose of selling them. A very few people among others from the Kendra involves in the practice of making caned furnitures. Initially the rattan stems are peeled with a sharp knife and the outer skins are removed from the vine structure. After the thin cane is obtained from the stem then each cane is segregated according to their types and sizes. Then by selecting a lengthy cane, it is cut with a hacksaw into a required length for the furniture. The cane is then heated with the help of a blow torch and is bent according to the desired shape by the craftsmen. The heated cane is further bent with the help of a shaping tool made of wood into a given shape. Each part of the furniture is bent separately one by one keeping in mind the size and the proportions of the furniture. As the craftsmen is making the sofa, he firstly makes the frame of the sofa using long canes. After finishing the frame of the sofa he and his helper starts working on the rest of the sofa. One by one each cane is shaped with the help of a blow torch and the burnt area is again cleaned with the help of the sharp knife. After the parts are shaped and the burnt marks are cleaned then they are kept in position on the frame and are nailed to the frame with a hammer to fix the position of the cane. The craftsmen with his helper nails all the parts accordingly to their placement on the frame. Each part is measured, cut and bent in proportions and then is nailed to their adjacent parts on the frame of the sofa. A wooden piece is used to give the perfect shape in the cane by bending the heated can into desired shape. The thin cane strands are firstly soaked in water to attain the moisture before weaving it around the frame. Thin long cane strips are peeled and are tied to the joints of the sofa to ensure the strength of the joints and the end is knotted in the cane strip itself creating a pattern on the frame. The complete sofa is achieved and then is polished using natural wood polish. Usually three coats of wood polish are used to give the cane a fine shiny appearance.

Flow Chart of Making Process: