Design Resource

Chick Mat Making - Gujarat

Chick Mat Making - Ahmedabad

by

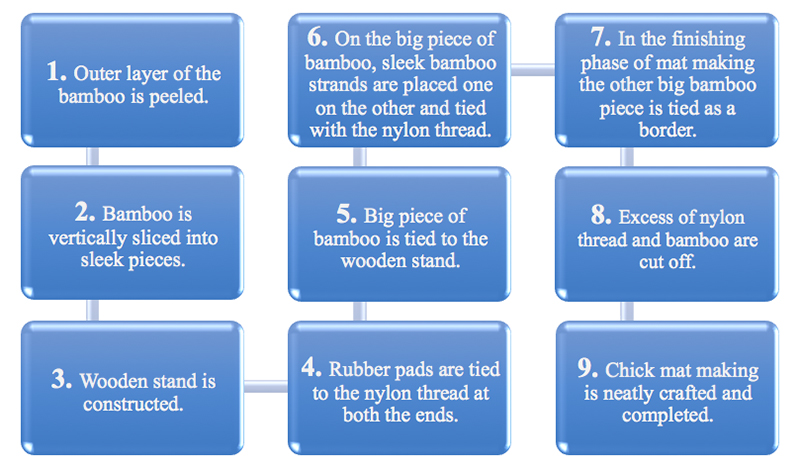

Chick mat making looks simple, but it takes lot of practice and hard work to gain the expertise. The whole of the family members get involved themselves in the process of making chick mat. The craftsmen begin the process by taking the customer’s order. The measurements of the windows and doors are taken. Initially the first outer layer of bamboo is peeled with the help of a knife. Then they are cut by the saw tool according to the measurements. Bamboo is made into two equal pieces vertically, later it is sliced into sleek pieces through the help of the sickle. The wooden stick is tapped on the sickle with a force, to slice the bamboo.

At a distance, big wooden beam is placed in the middle horizontally, by taking the support of the other wooden beams in both the ends, to make a stand like structure. After the structuring of wooden stand is made, the rubber pads are tied to the ends of a large nylon thread for the weight purpose. In some places instead of rubber pads even the stones are used. Numerous lengthy nylon threads along with the rubber pads tied at its corners are used for making a single mat.

Initially, the big piece of bamboo is tied to the wooden beam with the help of the nylon thread. From the second step the sleek bamboo strands that are sliced are kept one on the other on the big piece of bamboo and tied by the nylon threads, by rotating the nylon thread’s ends vise-versa so that the bamboo strand gets locked within the nylon thread. And this process continues till the required measurement of the mat’s length. And in the finishing phase of mat making the other big bamboo stick is added and both the corners of this bamboo stick is chiseled a bit for the grip purpose. This bamboo stick is also tied with the nylon thread at the end as a border for mat making. Later the extra nylon thread is cut and removed by the knife. The excess of bamboo strips, which are exceeding the measurement is also cut by the sickle and the crafting of chick mat is completed.

Flow Chart