Design Resource

Fiber Casting Statue - Ahmednagar

Sculpture Making

by

Prof. Bibhudutta Baraland Srikanth B.

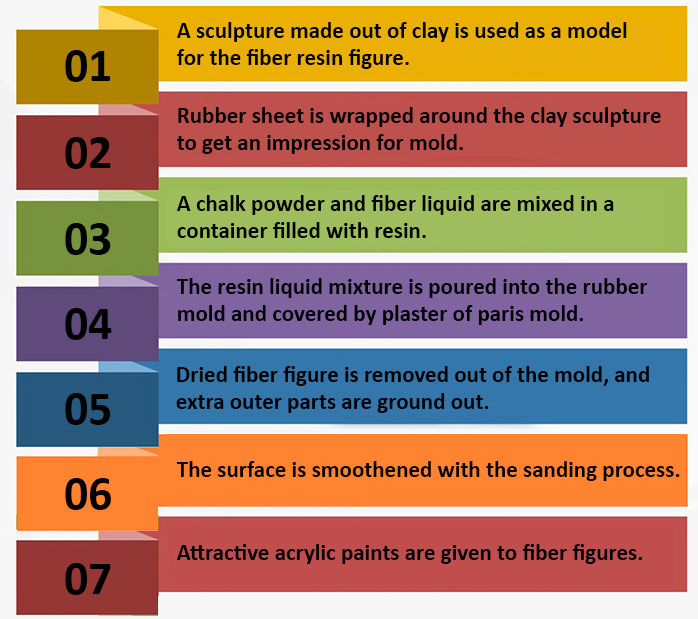

In the making process of fiber casting statues, the artisan starts with mixing clay powder with water in a container. Once the clay hardens to a consistency suitable for modeling, the artisan starts shaping the clay into an idol with hands, and details are given using a spatula set. Next, a rubber sheet is used to take the print of the sculpted statue from all its sides. This sheet is then converted into a rubber mold and placed carefully inside a solid plaster of paris mold. This step enables the fiber resin mix to be poured into the mold to take the printed rubber mold. For making this resin mixture, firstly the artisan mixes resin and chalk powder using a paddle mixer. Once blended to an appropriate density, fiber liquid is added to it. Shifting a small quantity of this into another container, the artisan adds hardener, which makes the casting tight and strong. The mixture of resin, chalk powder, and hardener is then poured into the rubber mold with POP mold supporting the outer part. After the mixture dries up, the external POP cover is opened and the rubber mold is removed to have a solid statue. Using a die grinder, the extra parts on this statue are ground, followed by resin and hardener mix application over holes and cracks that usually appear on a casted structure. After covering these areas, the artisan smoothens the surface with sandpaper. As a final step, this largely finished structure is then painted with selected acrylic colors to offer uniqueness and its share of attraction to lure customers.

Flowchart: