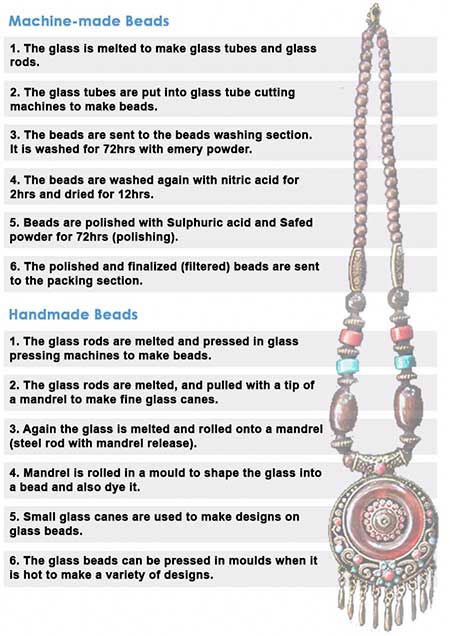

The making of glass beads can be accomplished in many methods, a few of which are handmade, tube cutting or pressing. The beads are produced in bulk with the help of well-equipped machines. The glass is melted and made into tubes or rods. The collection of certain glass tubes or glass rods is sometimes imported from China. The glass tubes and glass rods are often transported from the Firozabad factory and Purdilpur. Glass tubes have a hole which is why they are called tubes and glass rods are solid rods with no hole at the centre of the rod. The glass tubes are not melted while working with them. The glass tubes are put into a machine where they are cut into beads. The glass tubes are put into a bead cutting machine and the beads fall out from the machine and get collected. They are washed in water. Emery powder (aluminium oxide), Sulphuric acid and nitric acid are used while polishing and washing beads. In the first machine where the beads are washed emery powder of numbers, 600 and 1200 are used. The machine is run for seventy-two hours after which the machine is run for two hours again with nitric acid. The beads are washed and it takes twelve hours to dry. Then it is sent to the polishing section where sulphuric acid and safed (white) powder is added to the machine. This machine is also run for seventy-two hours and the process of polishing is complete. Working with glass tubes is an easy-go in gas it consumes less power and manual work. While the glass tubes are of cold process, the glass rods are often melted and pressed to make beads or they are melted and worked on them creating designs by hand. The glass rods are melted at high temperatures, melted glass rods are pressed with the help of a pressing machine. There are many sections such as glass tube godown, production section, tube cutting section, beads washing section and packing sections where respective works are carried on. Beads that are produced are dyed with help of coating dyes in a grinder. They are allowed dry and sent to the packing sections. Beads are filtered, they are sorted with the help of a sieve, the scrap beads are collected in a separate container, good ones or appropriate beads are divided into three groups and are sent to the polishing sections where they acquire luster, rainbow or other finishing. The beads are named according to their appearance- Round rocailles, 2cut beads, luminous, inside colors, fancy, metallic, dyed silver lines, transparent colors, and transparent Silver lines, transparent luster, opaque luster, Ceylonese, and so on. There are set of faceted beads which get colored. Faceted beads are beads that get cut like the one in diamonds followed by something like Tolkowsky. The colors used to paint on the faceted beads are transparent water-based colors. A few of them are Bengal Pink, Shimmer Bright Orange, VEL White, and Sun Yellow.

The beads are handmade- the glass rods are melted under the fire set up (bench burner) and the melted glass is pulled with a steel wire (mandrel) from one end, a small glass stick (cane) is made by pulling the melted glass to a length, this helps while designing the bead when making it all by hand. The melted is wound to a steel rod (mandrel) under the fire. There is a mold with dye color, after rolling the melted glass onto a steel wire it is rolled in mold with dye color this shapes the bead to a round shape and also the bead gets colored. The small sticks of glass are used to design the beads. On top of the round beads, dots are placed they are pressed with a flat tool to flatten the bubble and another round of dots are placed on the flattened design. Likewise, many designs are made with good color combinations which are very attractive. The melted glass after rolling to steel wire can also be pressed and shaped in molds when the glass is still hot. Handmade glass beads are final products where that do not undergo a washing or polishing process.