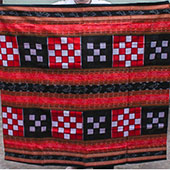

Ikat weaving is a kind of weaving that is well known all over the world. It is famously known for its intricate weaving process. This style of weaving uses a resist dyeing process as similar to tie-dye. It is an elaborate dyeing process in which yarn is dyed randomly in a natural zigzag style that is made of cotton or silk fabrics. Hence the final product is a piece of textile that is bathed and shimmered in colourful designs. Ikat weaving is unique, as it either uses the warp or weft to weave a design pattern. Sometimes they are tie-dyed using both warp and weft. Thus they are called as “Double Ikat”.

The unique characteristic of Ikat fabric is the blurriness of the designs. This blurriness is a result of the extremely difficult method followed while weaving, as the weaver lines up the dyed yarns exclusively so that the design patterns are attained in the most perfect manner on the completed textile. This blurriness can be reduced either by the skills of craftsperson or by using the finest yarns. As Ikats are most difficult to create with little blurriness, and complicated patterns using multiple colours therefore they are more expensive. Though the blurriness is the characteristic of Ikat, it is often prized by textile collectors.

Ikat is an Indonesian word that refers to a cord, thread or knot. The word Ikat is introduced into European language that is attributed to Rouffaer. Now Ikat is a general English word that is used to describe the process and the specific pattern of how and from where it has produced. Usually, in the Indonesian language, even the plural form of Ikat remains as Ikat itself whereas in English the plural form adds an alphabet ‘s' in common and considered as Ikats.

The unique pattern of Ikat is produced in various traditional textile centers all over the globe, from India to Central Asia, Southeast Asia, Japan, Africa, and Latin America. In Japan, it is also called as "kasuri". Bukhara and Samarkand were famous for silk Ikats since19th century while other countries have cultures with long histories of Ikat production. In double Ikats, as both yarns of warp and weft are tied and dyed before being woven into a single textile they are very rarely produced due to the requirement of intensive skilled labour. Such ikats are produced in Guatemala, Okinawa islands of Japan, the village of Tenganan in Indonesia, Villages of Puttapaka and Bhoodan Pochampally in India and it is also produced in Gujarat, India. The production and the patterns of Ikat vary widely from region to region. Generally, these Ikats are the symbolism of wealth, power, prestige and status.

It seems to have a link between the production of Ikat in India and South-East Asia. As the Gujarati merchants brought Patola (silk fabric) to Indonesian rulers and there the activity of Ikat production was taken over by the Dutch. Thus the patterns of the Patola Ikat are predominantly similar to the double Ikats produced in Bali of Indonesia. In Europe in Mallorca and in Spain Ikat floral patterns are used. Earlier using the technique of Ikat weaving shoulder cloth, turban cloth and lungi were produced. But today various products like bags, mats, sarees, bedsheets, dupattas, purses and files are made. When it comes to Odisha, it is mainly associated with Ikat saree production. Ikat patterns are dyes and bound into the threads before the cloth is weaved. This particular process differentiates it from the tie and dye process where the fabric is woven at the initial phase.

The technique of Ikat seems to have its origins in different places of the world. Ikat is one of the most ancient techniques of dyeing fabrics. As per the sources, Odisha Ikat dates back to the 12th century. It is said that artisans of Gujarat who migrated to Odisha carried onward the craft. Ikats practised in Odisha showcase three varieties. They are:

- Single Ikat – The process in which the yarns of either warp or weft are dyed.

- Ikat – In this procedure both the yarns of weft and warp are used together but in different parts of the single fabric.

- Double Ikat – Here both the yarns of warp and weft are tied in a precise manner. Thus the threads from both axis form a mesh with each other at a certain point to showcase the complicated pattern of that particular fabric.

Odisha Ikat sarees have appealed to the tastes of celebrities like Aishwarya Rai Bachan to other world leaders. Though the maintenance of the Odisha silk Ikat sarees seems to be easy, they need to be handled with care by a gentle hand wash or dry cleaning and a moderate temperature level has to be maintained by ironing. For cotton Ikat sarees the machine wash can also be done, still, it is better preferred for dry cleaning. In the production of Odisha Ikat sarees, they are traditionally practised using hands. These days to meet the modern rising demand, the making of these Ikats has been modernized. Thus in some places, they are carried out in an automated manner using machines.