Design Resource

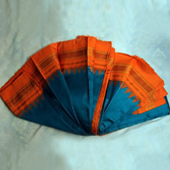

Ilkal Saree - Ilkal (Bagalkot), Karnataka

Traditional Styles of Sarees

by

Handloom Weaving:

Ilkal saree is woven in cotton along with art silk, with a border and a pallu of art silk or in mixed art silk and cotton. It is also woven with a silk border and pallu or even a body of silk and cotton with a silk border and pallu. Saree’s with a pure silk body, border and pallu with silk, art silk or cotton are later introductions. Gomi border and chikki paras’ border are the two types of borders observed in the Ilkal saree. Chikki means dots or stars and kaddi, kondi means small or big, dots or stars. The two borders look similar except that the triangles are smaller in the kaddi chikki and can be used in more number. Silk yarns basically brought from Bengaluru, silk along with cotton and art silk are generally preferred for making of the saree with either pure or combinations are chosen as per the weaver/ craftsmen. As per the craftsmen, in about 2000 people living in this village previously all the people were involved in the weaving, nowadays only about 1200 people have stayed back in continuing this craft. The coloured yarns brought in the hank form are wound on the bobbins/ pirns, which are later taken to the loom as the warp or weft. Piecing is the process where the warp yarns are knotted with the locally available substance called Minusari to knot the yarns firmly together to each other. In Ilkal saree making also follows the looping method where the pallu warp and body warp are attached. Some craftsmen follow the pallu weaving first and then the body part of the saree weaving.

Powerloom Weaving:

In order to save time power loom is also used for weaving the Ilkal sarees. Few weavers brush the yarns on the loom evenly and apply water to it with the bear hands. Then applies the colour mixture solution on the top, bottom portions of the yarn and allows it to dry, simultaneously weaving process goes on. Earlier natural colours were prepared by the craftsmen themselves and dyed; nowadays they have changed on to the synthetic dyes as it is the tedious process. Between the lengths of each saree about 15 cms of yarn is left and the next saree is woven. Each saree is cut from the loom and given to the elderly women of the house who engages in tying beautiful fringes with the left over yarns. After which the saree is folded neatly and sent for packaging process which is then distributed to the customers in request.