Design Resource

Leather Toys - Indore, Madhya Pradesh

Handicrafts of Leather

by

Prof. Bibhudutta Baral and Sandhya B.

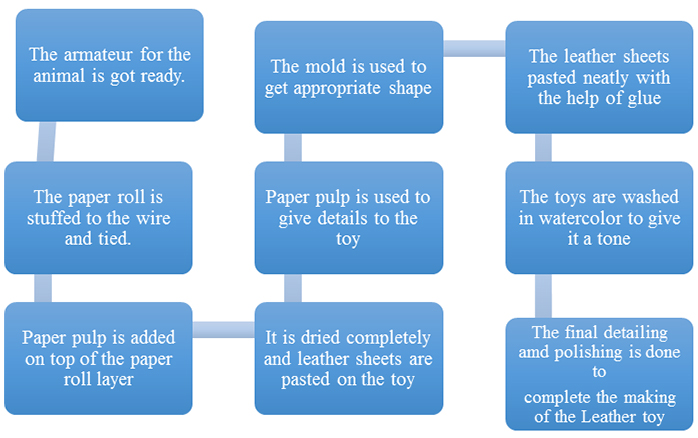

The armature for the required animal is made ready. The GI (galvanized steel wire) wire is bent according to the animal that is going to be made. Required amount of paper is rolled and tied to the armature. Mold of the animals that is pre-made is used. Paper pulp that is prepared like a fine clay paste is put on mold and then the idol is made ready. The mold is brushed with oil and paper pulp is spread over the mold and the casting of it is done. The edges are corrected and additional details like details facial features and curves for the body part are added to the toys. The paper pulp covered toys are left for drying in the sun for three or four days. Later it is covered with a sheet of processed leather, the leather sheet is neatly stuck with the help of the glue. Water colors are used to give a coat of color to the toys. The products are washed in watercolor and kept for drying. The eyes are attached and final touches are done to complete the toy making. The toys that keep the market running are the elephants, giraffe, horses, camel and tigers. The process remains same for any size of the toy varying in the duration of time taken to complete the making.

Leather - The leather is obtained from Hyderabad, Kanpur and Madras sometimes otherwise it is got mainly from Indore. Good flexible leather is used and a tone of color can be given to the toys by washing with watercolors.

Paper Pulp - Paper powder and tamarind seeds powder are soaked in water for two days and grinded well to make fine clay like paste. This paper pulp is used to mold and caste the animal toys. It is used to give correct features to the toys. It can be used just like the clay to shape the animal. The toys are dried in the sun otherwise it is difficult to carry on with the process. The making of toys during winter gets little hindered as they need the products to dry under sun.

Mold - The molds of camel and other animals are kept ready for the fast completion of toy making process. After stuffing the paper roll a coat of paper pulp is applied and placed in a mold with another layer of paper pulp in it. The molds when joined together complete the features of the animal and details like eyes, depth and body curves are hand done and finished.

Flow Chart: