Design Resource

Metal Crafts - Balakati, Orissa

Metal Craft Making

by

Prof. Bibhudutta Baral, Divyadarshan C. S. and Amulya S.

Traditional Artisans and Craftsmen from Balakati, Puri district, Orissa brings an enormous energy and skills in production of the Brass Metal utensils and articles. Ten members work in a studio, were the craftsmen bifurcate themselves in different processes. There are two major different production ways of metal craft one is Dhokra casting and other one is Pita (locally known). Craftsmen of Balakati follow Pita work habitually.

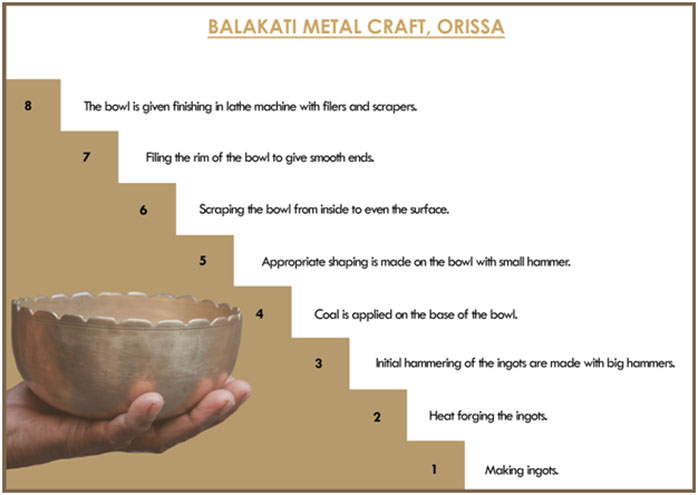

There are two types of alloys which make brass and bell metal, those are copper plus zinc and copper plus tin. Any one of these two are mixed in proportion in a crucible in furnace which is locally called Bhati. If copper is of one kilograms, zinc is quarterly measured to it that is two fifty to three hundred grams required in making brass metal. The molten metals are put to the small earthen moulds and the metal is acquired into small circular metal casted ingots. The circular cast ingot is pre heated on the open furnace to make the metal soft, malleable and it is hammered repeatedly with big hammers in rhythm by three to four people to get into its desired shape on a stone platform with one person rotating the ingot piece to acquire the even dents. The metal ingot is annealed or heat forged in regular intervals between hammering with the purpose of keeping the metal soft enough for further process. The new metal ingots are placed in between the half hammered ingot in order to produce more bowls within less time and energy. There can be four to five metal ingots placed one upon one in this process. Once the outer ingot turned bowl is expanded appropriately it is removed with the help of foundry tong or pincers and hammer. The base of the bowl is painted with coal mixed with water because coal observes and endures the heat and helps while shaping the bowl. When the metal ingot turned bowl as acquired the desired shape it is furtherly processed through many finishing process like shaping, scraping, buffing and finishing is made on lathe.

Shaping in the sense raising the bowl out of flat metal or half raised metal by beating it into depression and maintaining the thickness of the metal equally everywhere with hammer, on the strong metal dome anvil stakes. After shaping the bowl it is processed to scraping were the bowl is scraped from inside to even and level the surface and the rim of the bowl is filed for the smooth finishing. Subsequently the scraped bowls are given to the master craftsman to attest the bowl and uniformly give finishing on the lathe. The bowl is heated at the base by the ignited coal on the crucible and later the hot melted tar is applied like an adhesive to stick on the faceplate on the lathe. After sticking the bowl on lathe the electrical rotatory motor is on were the bowl starts rotating. Brass wire sponge is held in hand and rubbed inside the rotating bowl were the scraped markings are removed. Later scraping knife lathe tool is held in refining and finishing of the bowl by removing the unwanted layers. Sometimes the bowls and other brass articles made are etched and engraved in various designs including floral, ethnical, symmetrical patterns in order to enhance the product more in various chisels.