Design Resource

Mysore Silk

The Making of Silk Textile

by

Prof. Bibhudutta Baral J. Antony William and C. Susanth

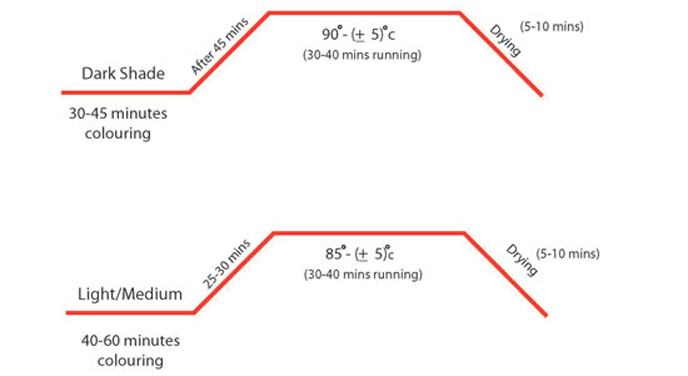

Colouring:

Machines called winches help in the colouring of the sarees. The factory has both the big winches that can accommodate 40 sarees and the small winches that accommodate 24 sarees for couloring purpose. The sarees are rotated on a frame on a horizontal axis inside a tank. The tank contains hot water and the tank is connected to a colour tank through a pipe. The colour, is in the form of a liquid and is determined from the shade card that is provided by the marketing team. About 450gms of colour is required for 48 sarees depending on dark shades or light shades. If the colour is not properly applied, then the entire saree is bleached again and the colouring process is repeated again. During the colouring it self the sarees that were stitched together manually are taken out.

Contrast colouring:

The coloured sarees are clamped in wood fixtures in plastic bags and the border is left exposed. A clamp consists of 4 sarees. The border is dipped in water at 120 degrees and colour is added. This process takes about 15 -30 minutes. The workers wear protective gear such as boots, masks and gloves as the colour is extremely toxic. The sarees are then washed with water to remove excess colour and sent for hydro-extraction.