Design Resource

Papier Mache Mask - Panaji, Goa

Crunched Paper Art

by

Prof. Bibhudutta Baral, Divyadarshan C. S. and Rakshitha

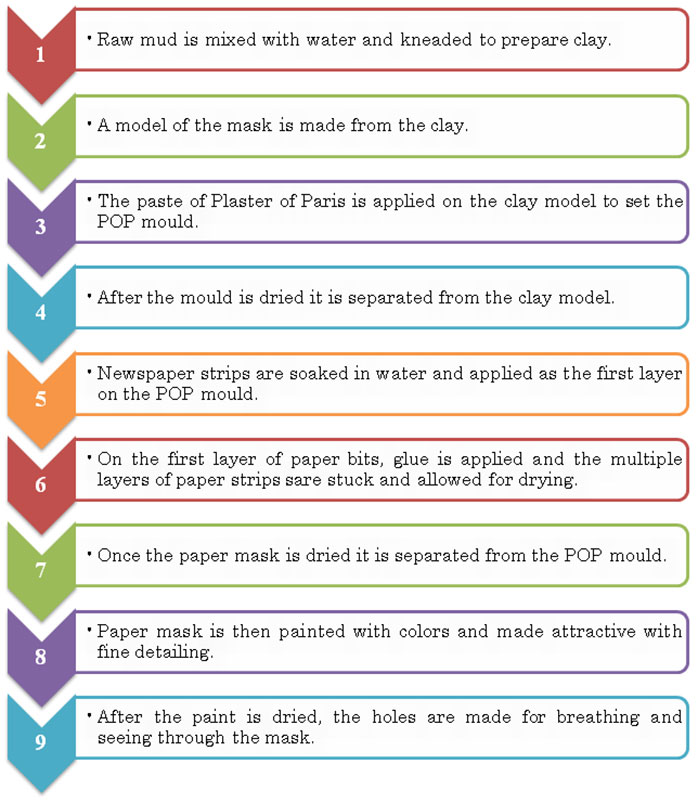

The process of making papier mache mask begins by preparing the clay model as the most fundamental startup procedure. Mud is mixed with water and kneaded thoroughly for making clay. This clay is used for preparing a model for the mask. Once the clay model is prepared and dried, the paste of plaster of Paris is applied on it and the moulding is done. After the POP moulding is dried, the clay model is removed/separated from the mould.

Once the mould of plaster of Paris (POP) is prepared, newspaper is shred into several strips and soaked in water. The number of newspaper strips depends on the size of the face/mask. These paper strips are applied one by one on the inside portion of the POP mould. Usually the horizontal wide strips are laid on the jawline and forehead regions of the mould and the longer vertical strip’s on the nose region. After completing a layer of applying the paper bits on the mould, the dry newspaper bits/strips are stuck on the wet paper bits using the glue. This glue is also a preparation of the artisan. Maida flour mixed with water is blunt until the paste is smooth and reaches the gluey consistency. This paste is used as the glue here. By using this glue the multiple layers of newspaper strips are stuck one on the other by overlapping the each strip with a new one and pressed with the cloth to wipe out the glue that is excess and it is dried. After the layer of paper strips are dried, it is removed from the POP mould and the holes are made as the nostrils and other two holes are made in the eye region for the wearer to see. Later the paper mask is completely painted with acrylic colors and made attractive by giving the fine detailing of the features. Here the acrylic colors are most likely preferred for painting because they are thick enough to cover the pictures and words that are on the newspaper strips. Once the mask is dried it is sold according to the customer’s requirement/need.

Flow Chart: