Design Resource

Pottery Making - Kanyakumari, Tamil Nadu

Clay Decorative Objects

by

Prof. Bibhudutta Baral and Sowmya B. N.

The machine used to make pottery is called jollying or jiggering was developed in the 18th century and is a mechanical adaption of wheel throwing. This method is used to produce mass amounts of one shape. Similar to a potter’s wheel, it has a large head which contains a mold of the desired shape, such as plate, cup or bowl. The inner part of the object is shaped by a metal profile, which moves against the clay.

Clay preparation: The first step is to clean the clay of any extra material. Then, mix it with water flexible blend is obtained. The next process is beating and kneading the clay. Beating removes air bubbles. Soften the clay and then a plaster mould is placed in the chuck and forming is done by bringing down the inside template.

Two types of mould is used in pottery making:

• One piece moulds: usually, moulds are only made in one piece. Because the product needs to be easily removed from the mould. Moulds must not have any undercut which might catch the clay. Also, there should not be any sharp edges- foot rings must be rounded and not very high.

• Two-piece moulds: Sometimes, two piece moulds are used for shapes that curve in slightly at the top.

Once the clay is prepared the clay is thrown into the revolving mould to make pottery. Basically, the jigger machine consists of a spinning wheel head which is fitted to held plaster of parts moulds and a movable arm which holds a metal profile. Clay is placed on mould and the operator purls down the profile, which forces the clay into the shape of the product. The forming method is called jiggering.

Place the mould under the jiggering machine. The clay is mixed well and thrown into the revolving mould. Then the arm is pulled down and the piece is shaped. When the pottery has stiffened enough hold its shape, it is removed from the mould and edges are trimmed and is kept for drying.

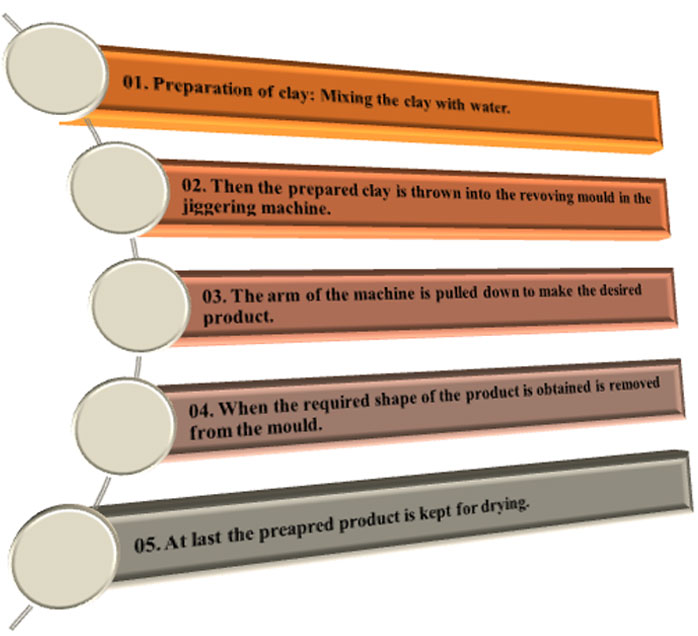

Flow Chart: