Design Resource

Screen Printing - Varanasi

Printing Technique

by

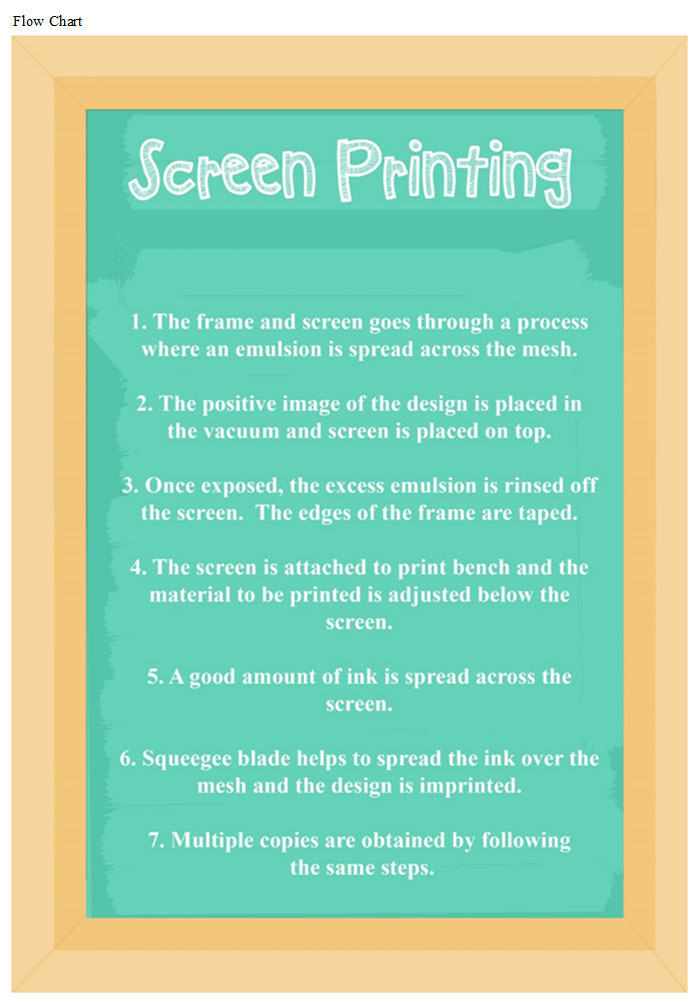

The frame and the screen go through a process where an emulsion is spread across the mesh and the exposure unit burns away the inessential emulsion leaving behind a clean area in the mesh with recognizable shape as the preferred image or design. There are various sizes of mesh, the appropriate mesh is coated with emulsion and put to dry which is then suitable to expose. The design that has to be obtained is placed on the screen and then exposed with a light source containing ultraviolet light of certain Nano meters spectrum. The screen is washed thoroughly and few minutes of exposure. The design is clear for the ink to pass through, and the screen with necessary design is equipped to begin with the process of screen printing.

The white fabric is cut to required lengths. It is sent to the dyeing section when colouring is required otherwise it is directly taken onto the table to screen print. The white fabric is spread on the table at marked spaces, and with the help of screens the designs are stamped on to the fabric. A squeegee helps the movement of the ink. Ink is poured onto one of the sides on the screen and squeegee is moved from one side to the other ensuring the ink to have passed through the screen. The colors used are acid colors, pigment and non-metallic colors. These color powders are mixed in appropriate proportions along with white agent and is kept for heating. Once it reaches a good liquid state it is poured to a thick good amount of white paste to prepare the ink it is stirred well and used when required for the portion of fabric to be printed. This way the color is prepared, checked on a piece of white fabric before beginning to use, after this is the required design imprinted on the fabric. There are unlimited designs that can be used and they change as time pass by depending on the place and likings of the people of respective places- In Jodhpur cotton fabrics are preferred comparative to the other fabrics, Kalamkari is noted in Andhra Pradesh, and Bandhani is known in Gujarat. Designs get better as time goes by and according to the requirement of customers. Once the design is printed on the fabric it is allowed for the ink to settle. The fabric is later washed, rinsed and kept for drying. It is checked for packing, final cutting and stitches are made and sent to packing which are later dealt with exporters and reach market.