Design Resource

Screw Pine Craft - Thrissur, Kerala

Craft from Flowering Plant

by

Prof. Bibhudutta Baral, Divyadarshan C. S. and Sandhya B.

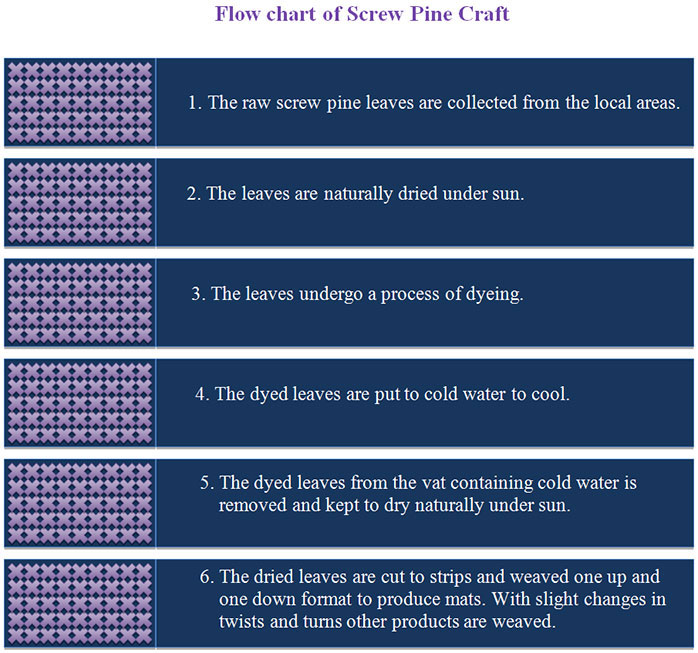

The large flowering plant- screw pine, grows rivers side mostly, and is collected from the people of that region. The screw pine products makers get these raw materials from the local areas and continue with the further process. The people are trained for about a month and later they come up with new designs and the designs appealed by clients.

The screw pine is cut with the help of cutters or knives and collected. The leaves are dried well to straighten the screw pine leaves. It is sliced to required widths. The leaves then undergo the process of dyeing where the leaves are put to boiling water along with respective dye powder that is been added. To a tank that has capacity to hold 400 liters is filled with water and kept for boiling. Along with screw pine natural products of 5kgs, 150kgs of color powder is added to the tank. The leaves take the respective color. They are taken out of the tank and put to another vat of cold water to cool it down. The leaves then are kept in the sun to dry. The leaves that have dried under sun are then sent to the weavers department to continue with the weaving process. The leaves are ready to be weaved to suitable products. Weaving- the weaving of screw palm leaves is one up and one down plain weaving arrangement by hands. A lot of products adopt same process with a slight change in twist and turns of screw pine leaves. The screw pine products are weaved to sheets and then cut to the desired shapes. For a coaster, a round shaped cardboard is taken and placed on the sheet of weaved screw pine and a circular is drawn. Weaved screw pine is cut to two circular shapes. The cardboard, which is of same size of the cut screw pine, is placed and glued in between and stitched at the ends. The stitch looks neat and ordered with experienced artisan. Few other products like coasters for plates, mats follow the same technique. With the appropriate weaving of screw pine, incredible products can be obtained.