Design Resource

Single Wire Craft - Ahmedabad, Gujarat

Creating Model with Wires

by

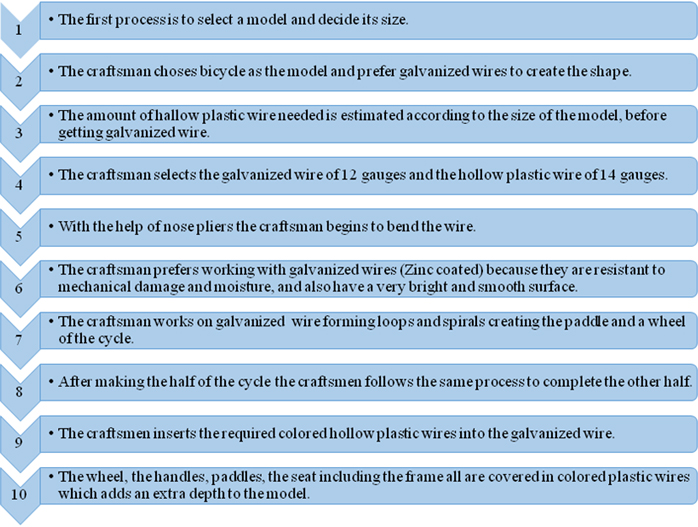

A skilled artist who has experience in handling metal wires can prepare single Wire craft. The first process is to select a model and decide its size. As per the difficulty in the model a suitable wire is selected to shape it into the model. The craftsman selects a bicycle as his model and prefers galvanized wires to create the shape. Before selecting the galvanized wire and the coloured hollow plastic wires the size of the model is calculated because if the model is small one should buy 28 gauge galvanized wire and 26 gauge hollow plastic wire. The plastic wire is always a size bigger when compared to the galvanized wire so that it can be easily inserted into the galvanized wire. Generally the craftsmen use wires ranging from 10 gauges to 28 gauges. The raw materials are purchased from the local markets. The craftsman selects the galvanized wire of 12 gauges and the hollow plastic wire of 14 gauges. With the help of a diagonal plier he cuts out the required length of the hollow plastic wire, which will act as a color to the model and inserts the galvanized wire into it.

As it is a single wire craft the craftsmen without cutting the galvanized wire starts his initial process of bending the small half of the uncut wire with the help of a nose plier. A nose plier enables the craftsmen to smoothly bend the wire into any shape. The craftsmen being familiar with galvanized wire knows exactly where to bend the wire equally without distorting it. The craftsman prefers working with galvanized wires (Zinc coated) because they are resistant to mechanical damage and moisture and also have a very bright and smooth surface. The craftsmen places the exact amount of hollow coloured plastic wire needed in the particular bend and with the help of a nose plier he continues rounding the wire to its center forming a spiral shape. The nose plier even helps in holding the shape firmly in place and allows equal twisting of the remaining wire into a shape required for the model. The galvanized wire forms loops and spirals creating the paddle and a wheel of the cycle. After making the half of the cycle the craftsmen follows the same process to complete the other half. In the beginning of the model the craftsmen inserts the required coloured hollow plastic wires into the galvanized wire, so that whichever part needs a colour the plastic wire takes its place. The wheel, the handles, paddles, the seat including the frame all are covered in coloured plastic wires which adds an extra depth to the model. With a lot of perseverance the craftsmen ensures the endurance of the completed model, which is created by assembling the galvanized wires.

Flow Chart: