Design Resource

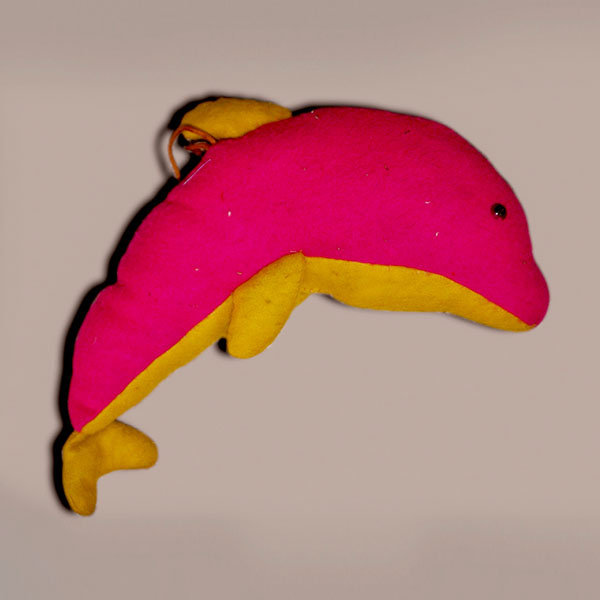

Soft Toys - Yadgiri, Karnataka

Stuffed toys for kids

by

Prof. Bibhudutta Baraland Srikanth B.

The making process of soft toys involves just a few steps namely; cutting, stitching and knitting. Hence it is often considered an easy and investment-friendly profession. Firstly the purchased fur fabric is marked with the intended pattern with a pencil. Here the plain side of the fabric is used to draw the pattern. Once it is done, the cloth is cut according to the design of the toy, using a scissor. Then the cloth is stitched and the edges are slightly pulled out. In the sewing stage, the seams are made on the back of the fur cloth so the stitch is not visible. Now the cut pieces are placed together according to their apt positions and again stitches are run to keep them connected. The details like nose, mouth, beaks, horns, etc. are often stitched separately and attached. For eyes, stickers, or readymade polymer clay eyes are used. The artisans also experiment with varied colour combinations for the toys in order to win the attention of kids or other customers. At the last stage of the making, a little space is left at the back of the intended structure as a cavity to fill in cotton fiber inside the toy. After filling the cotton, a fine stitch is made through them to ensure a strong joint.