Design Resource

Temple Pottery - Puri, Orissa

Extensive Form of Handicrafts

by

Prof. Bibhudutta Baral, Divyadarshan C. S. and Aakash Sharma

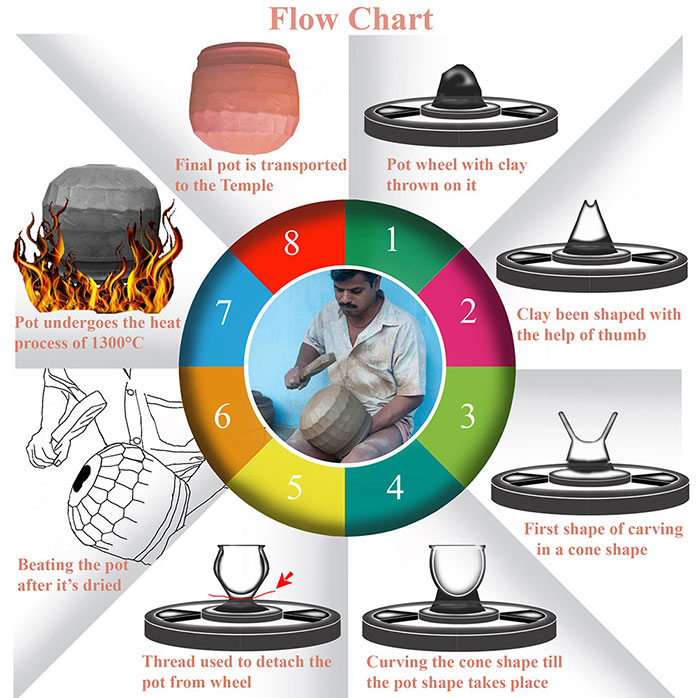

The Raw clay originates from the areas close to Sathi Gopal temple in a tractor which may last for about a month. The clay is mixed with water and drenched for a day after which, it’s been crumpled and mixed by hand. Clay is moderately mixed with wood powder and extracting of unwanted objected from the clay is practiced. After filtering of the clay, it’s been rolled until it forms to a soft clay. Artesian throws clay on the pot wheel, interchanges the wheel with the help of a stick placed on a one inch breach which benefits in spinning the wheel. Throwing the clay on wheel which is one of the main procedure, he starts to carve a pot out of the clay. Artesian places his thumb in between the clay and progressively starts applying pressure. Once a hollow shape takes place, he starts placing all his fingers and starts to gradually apply force in an equal manner. Cone shape is formed, the neck of the pot is bent towards upward and towards inside. With the help of thumb the compression is applied from the base of the pot towards edges to form a shape. Index finger and thumb helps in getting the edges precisely. Last finger gets edge shapes on the pot. Finally right hand goes into the pot by applying pressure with the help of left hand. Radius of the pot is equal with the help of this process. Once the shape is formed, artesian then detaches the pot with the help of a thin thread.

After placing the pot for drying which takes about a day, artesian checks for any minor cracks, keeps it on his laps and places an additional terracotta product within the pot by adding some ash for the surface to remain rough. He removes excess clay and beats the pot gently with the help of a curve shaped wooden tool. A layer of fresh clay is used to cover the base, after a gentle tap with the wooden object, water is applied on the pot as well as on the wooden tool, and artesian starts to hammer with the help of flat wooden tool (Bat shaped) following the same process. The hammering process takes place in the form of flat hit which goes flip flop by forming a dimensional shape. Pots are then placed on the kiln for the further burning process and it’s burnt for about 2 to 3 days. Kiln is filled with dry hay, plants from forest with some coconut shells to begin with the fire. After the baking process, temperature cools down, the final product is removed from kiln and supplied on a manual transportation. All of this products are supplied to the temple. There is always a demand from the temple as all of the holy food is been stored in this pots.