Design Resource

Wood Carving - Furniture

Craft of Wood Carving - Warangal

by

Prof. Bibhudutta Baral, Divyadarshan C. S. and Lija M. G.

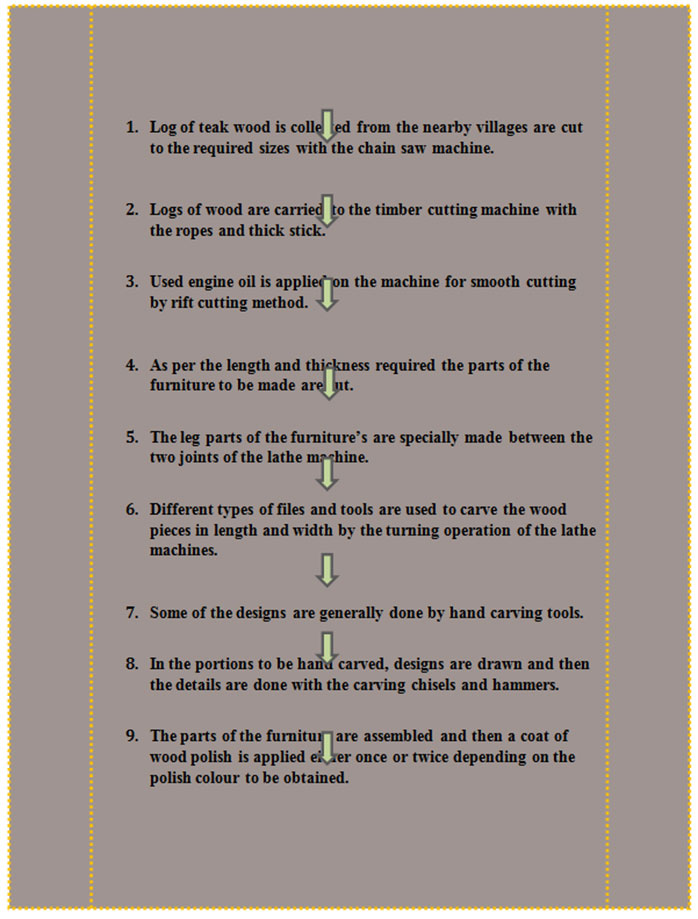

Logs of teak wood taken from the neighboring villages are collected where the timbers are gathered and cut to the required sizes with the chain saw machine. Cut logs of wood are carried to the timber cutting machine by the craftsman with the help of ropes and thick stick. When the logs are placed on the machine, used engine oil is applied on the machine for the smooth cutting by the Rift cutting method.

Log of wood are converted to cut pieces as per the thickness, length and it is taken for the parts of the furniture. For the designs of the leg parts of the furniture it is placed between the two joints of the lathe machine. Various files and tools are used to carve the wood pieces as per the required length and width by the turning operation of the lathe machine. Other designs are generally hand carved by the hand carving tools.

With respect to the other parts of the furniture it is hand carved, the craftsman draws the design to be carved on the surface and then the details are drawn. The unwanted portions of the wood are taken out followed by the removal of the unwanted parts by the carving chisels and hammers. Fine and intricate designs are carved at the end where the craftsman takes time and does all things in detail.

After the detail carving is done it is then applied a coat of wood polish once or twice as per the requirement of the polish colour to be obtained. These craftsman does the items usually as per selection and requirement of the customers.

Flow Chart: