Manufacturing Process of DHOLM Composite

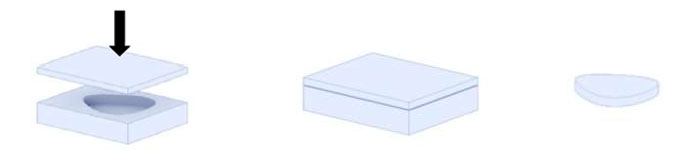

To make a solid and compact DHOLM composite, the hot composite material is poured into the mold of the desired shape and size after it has been cooked. With a spoon or other flat object, the bulk preheated material is pushed into the corners. Compression can be done in two ways. One method is to use a flat metal plate/wooden piece and the other method is to use a metal plate/wooden piece that is the same shape as the mold as a press die. When using a flat metal plate/wooden piece, additional material must be added to the mold so that when pressure is applied using a hydraulic press at 100Pa, the hot material is properly pressed down into the mold. The pressure is kept on until the cure is achieved. The composite is removed after the mold has cooled.

Fig. 26 Wooden Compression Mold for prototype

Fig. 27 Compression mold process

Machinability of DHOLM Composite

The machinability of natural fiber composite depends on the physical properties of the materials used for making the composite. Some of the main processes like drilling, grinding, and sanding was done in order to check the machinability of DHOLM composite.

• Drilling Process - Drilling is a cutting process in materials by using a drilling machine. Due to their poor sensitivity to heat damage and weakness in the thickness direction, drilling composites was more difficult than drilling metals. Owing to the fragile nature of the composite, chips were formed during drilling.

• Sanding Process - Sanding is a process of smoothing or polishing a surface with sandpaper or sand. The composite does not chip as a result of the increased speed and heat produced by the grinding tool, and the shearing of materials is visible. Creating a smooth, glossy surface that gets hot and soft. The finish of the surface is determined by the grinding tool used.

• Grinding Process - Grinding is a process of removing material from a workpiece via a grinding wheel. As the grinding wheel turns, it cuts material off the composite while creating a smooth surface texture in the process.

• Sawing - Sawing is the process in which the saw is formed as a band and is continuously cycled in one direction around pulley wheels. This enables a continuous cut to be made. A smooth cut was achieved by cutting the composite perpendicularly with a bandsaw. The finish is determined by the bandsaw's speed; the slower the speed, the more chips are formed.

Chip Formation

As the point of the cutting tool contacts the metal, some compression occurs, and the chip begins flowing along the chip-tool interface. As more stress is applied to brittle material by the cutting action, the metal compresses until it reaches a point where rupture occurs and the chip separates from the unmachined portion. Discontinuous chip formation is seen in the DHOLM composite as dhoop is a brittle material. Following the selection of the machine tool and cutting tool, the key cutting conditions of cutting speed, depth of cut, and feed rate must be considered. When drilling the DHOLM composite, process parameters such as spindle speed and feed rate are heavily influenced by the tool's material and geometry.

While drilling is the most common method of machining Natural fibre composites, milling and turning are also widely used in some applications to a lesser extent. Drilling, sawing, sanding and grinding composite materials can all be done with traditional machining methods. The proper tool geometry and operating conditions must be used to reduce the amount of heat produced and prevent thermal damage to the component.