The MPD design was achieved by following the six criteria that form the backbone for innovation by design process. The criteria are elaborated below as:

• The Cause - Identifying the Need:

Before 2000, Indian markets were dominated by only one kind of petrol or diesel. Thereafter, different choices in the same started appearing and hence dispensers capable of satisfying this need arose. Thus in 2001, MIDCO saw this as the new potent direction in this market and started developing its own multi-product dispensers.

• The Context - Understanding the User and Scenario through Research:

Computer aided design was gaining greater focus along with Project Lifecycle Management tools at this time. Hence an extensive use of both was done to reduce the design to product time and streamline the design, manufacturing and assembly.

POS (Point of Sale) systems became very important at this time so that the oil companies could monitor sales. This monitoring helped them in better organizing the distribution of fuel to different locations.

Fuel stations wanted to use single submersible pumps at the fuel tank rather than installing each dispenser with a pump.

• The Comprehension - Drawing insights from the Data Collected:

From a detailed study of the context, following insights were drawn:

- Multiple designers can work simultaneously on different parts of the product design thereby reducing design lead time

- Advanced CAD and PLM can offer greater modularity and accuracy in design features and thus allow customization to a higher degree

• The Check - Evaluating Designer insights against Client's brief:

The project was initiated with the following brief:

- A product, which can dispense multiple fuels.

The insights drawn from the contextual exploration further added the following dimensions to the brief:

Design for

- Ease of manufacturing

- Ease of assembly

- Service

- New materials

- Modularity

- Identity

- User convenience

- International marketing

- CAD & PLM integration

• The Conception - Creating Ideas:

Thereafter, multiple ideas to resolve each problem identified within the framework of the product brief were drawn out. The ideas were then grouped into clusters on the basis of their affinity to particular criteria of the product brief. The clusters of ideas were then amalgamated to form concepts, which address all the requirements of the product brief. These were then evaluated by making full-scale prototypes to arrive at a single final concept, which combines the best features of all the clusters.

• The Creation - Converting Ideas into Product:

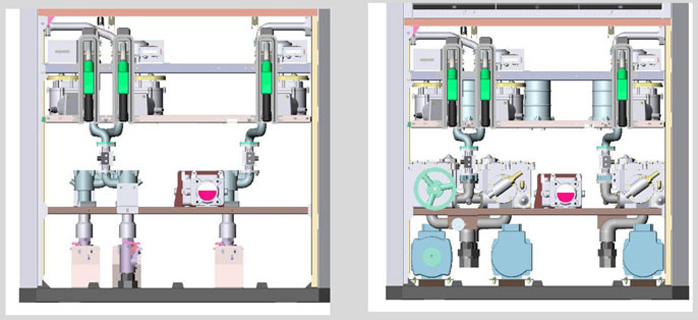

Following the design methodology, as illustrated in case of Z-line, the first prototype was designed and built. The dispenser followed a chassis based approach where in depending on customer requirement, a pump can be installed or it can be connected to pipes from a submersible pump at the fuel tank. The make of the meter could also be changed depending on the requirements of the oil companies. POS (point of sale) systems could also be incorporated on demand. Highly modular design reduced the number of components and hence the price.

MPD Pump Design Downloads:

• MPD Pump Design Case Study - pdf