The Z-line design was achieved by following the six criteria that form the backbone for innovation by design process. The criteria are elaborated below as:

• The Cause - Identifying the Need:

The driving force that led to the commencement of the project was the fact that till 1986 L&T had the maximum market share in fuel dispenser business but thereafter the competition caught up and L&T was losing ground rapidly. The competitors brought in new models inspired by the models in the international market. As the competitors were smaller companies, their overheads were low and hence L&T was losing orders, which in this market is based on L1 (lowest bidder wins the tender). Hence L&T needed a superior product that is at least 25% cheaper than the current L&T dispensers.

• The Context - Understanding the User and Scenario through Research:

To gain a good grasp of the context, a detailed study of the history of fuel dispensers (Indian & International), manufacturing processes, usage scenarios and contemporary style trends was done. History of fuel dispensers clearly indicates a homology between the formal and technical language of cars of that period. Dispensers in the international market varied in degrees of sophistication and simplicity depending on the nature of the market. This indicated that rather than concentrating on global design, the need for the hour was local design. Modularity was identified as an important feature that can reduce the price of the product. A study of style trends of the period was inspired by cars of that period. The dynamic angular looks formed the basis of these forms. Hence the definition of contemporary was achieved.

• The Comprehension - Drawing Insights from the Data Collected:

From a detailed study of the context, following insights were drawn:

- Emphasis has to be given to local design rather than global design as the requirement of the markets are very different.

- Inspiration from the auto industry can be drawn to manufacture the gaskets and glass assembly of the dispenser.

- Oil companies demand for customized features.

- User Interface

(a) Fuel station owners use the meter to see the total fuel dispensed at the end of the day. As it was placed inside the dispenser, the owner had to use a torch and get in to see it.

(b) Servicing the electronics of the dispensers was difficult due to access issues.

(c) The fuel stations didn’t usually have a top canopy. Hence the LEDs were not visible in the daytime whereas LCDs were not visible at night, as it is not glowing.

- Manufacturing

(a) L&T had a high-end CNC manufacturing setup which can be utilized to the optimum through product design.

(b) To enable ease of painting, each sheet metal panel should have a small hole to hang the panels.

(c) L&T had a very skilled manpower on the assemble line that can be used optimally through product design.

• The Check - Evaluating Designer Insights against Client's brief:

The project was initiated with the following brief:

- The cost of the new modern pump had to be 25% less than the old one

- The product should have a life of at least five years.

- The form of the petrol pump had to be strikingly different so that it could create an impact in the market.

- The hydraulics organization should not be changed.

- Existing manufacturing facilities had to be used.

- Construction had to be in Sheet Metal

The insights drawn from the contextual exploration further added the following dimensions to the brief:

Design for

- Ease of manufacturing

- Ease of assembly

- Service

- New materials

- New painting system

- Skilled manpower

- Modularity

- Identity

- Station owners

- User convenience

• The Conception - Creating Ideas:

Thereafter, multiple ideas to resolve each problem identified within the framework of the product brief were drawn out. The ideas were then grouped into clusters on the basis of their affinity to particular criteria of the product brief. The clusters of ideas were then amalgamated to form concepts, which address all the requirements of the product brief. These were then evaluated by making quick prototypes out of paper and thermocol.

• The Creation - Converting Ideas into Product:

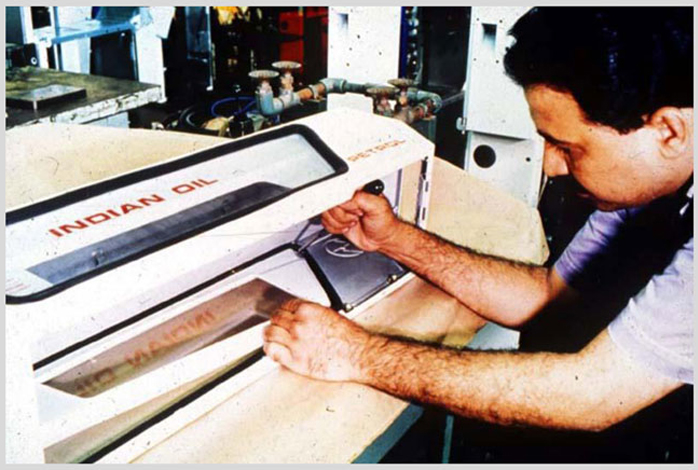

The ideas were thereafter grouped into clusters and some concepts were created. These were thereafter modeled as full-scale prototypes and all stakeholders were invited for a detailed discussion. The selected prototype was manufactured by using high-end CNC machines. The gaskets to avoid water ingress were the same as used in Maruti cars, enabling availability of superior quality product at low price (benefit of mass production). The electronics chamber was made accessible to easy servicing by designing a hinged display panel, mounting all cards on metal brackets and clean wire harnessing. Different graphics suited to oil companies branding was also achieved. Multiple display provisions were made so that customization can be achieved as per oil company demands. The pump has both a LED and LCD displaying the same information.

Z - Line Pump downloads:

• Z - Line Pump Case Study - pdf