The mould is developed from a pattern and is made up of plaster for its ability to absorb water from the slurry as elaborated further. It is divided into two or more parts depending upon the complexity of the pattern which is explained in detail in the animation.

The area required to make the mould should be left open; closing the rest of it to ensure that the mould takes the desired form. Also, apply some oil or washing liquid as a separator to the plaster pattern. This will ensure that the pattern can be easily removed from the mould after casting.

It is essential to make the mould into minimum parts leaving enough space for carefully assembling them in a proper position.

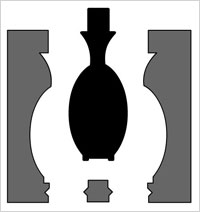

The mould in the picture below is made into three parts. It is not feasible to make the mould in less than three parts and making it in four parts will degrade the quality of the product. Also, it is time consuming to match and fix the increased number of parts accurately. Hence, in this case it is most feasible to divide the mould into three parts to be very accurate.