Snap fits are most economical and rapid methods of assembly for high volume production. Snap-fits may be a detachable or a non-detachable joint. All snap-fit designs consist of two basic parts. First one is a flexible member which is acting like a cantilever which bends and returns to its original position during snapping action. The second member holds the cantilever having sufficient space to accommodate the flexing of cantilever. Snap-fits can be broadly categorized as cantilever snap-arms and annular snap joint. The shape of the undercut determines whether the joint can be separated or not. Snap-fits with angled undercut can be disassembled easily. Snap-fit provide both secure as well as easy assembly of the parts. They facilitate easy and quick detachment of electrical components for repair.

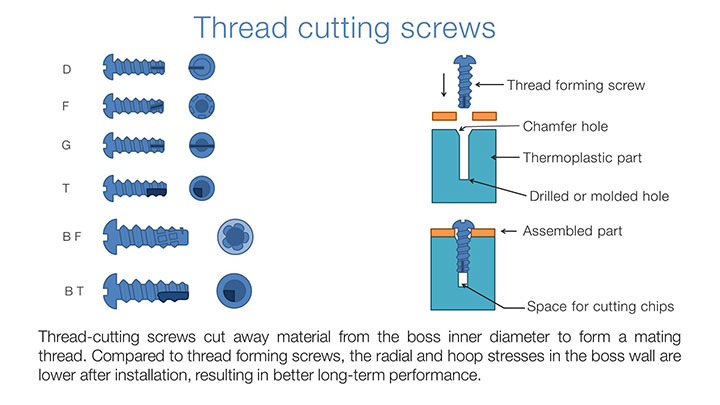

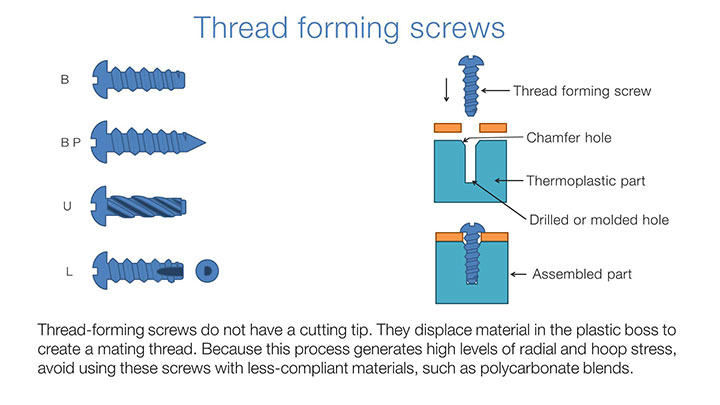

Thread forming screws deform the material when inserted, forming threads in the plastic parts whereas thread cutting screws remove the material and form the thread. The selection of self-tapping screw depends on modulus of elasticity of the plastic used.

Design considerations

• Thread forming screws – when modulus < 1380 MPa

• Thread cutting screw – when modulus is in between 1380 MPa to 2760 MPa

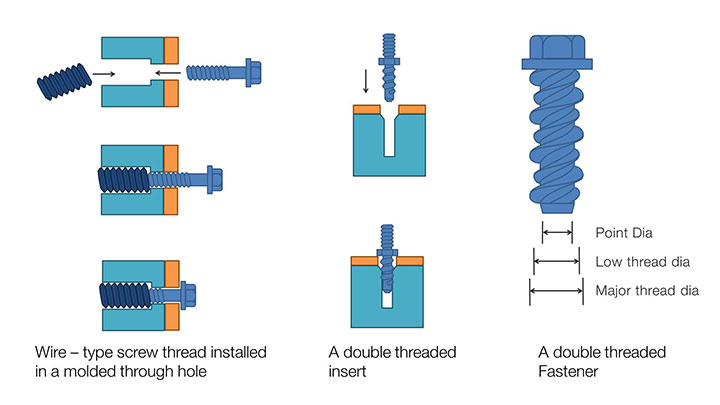

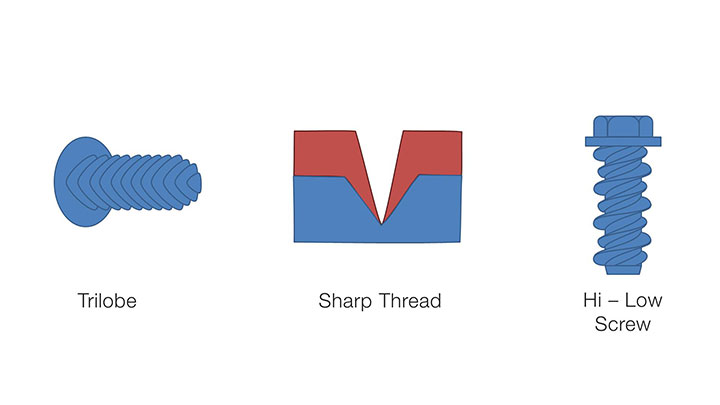

A trilobe is a thread forming screw having three swaging lobes which displaces material as screw drives into the hole. Trilobe allows the displaced material to cold flow back into relief areas which minimizes radial stress and reduces possibility of boss failure. Sharp thread are those in which the included angle is of 30 degrees or 45 degrees which makes sharper threads that can be forced into ductile plastic more readily which create deeper mating thread and reduces stress. Hi-Lo fastener has double lead thread where one thread is high and other is low. Hi-Lo fasteners have higher holding power due to the increased amount of plastic captured between threads.