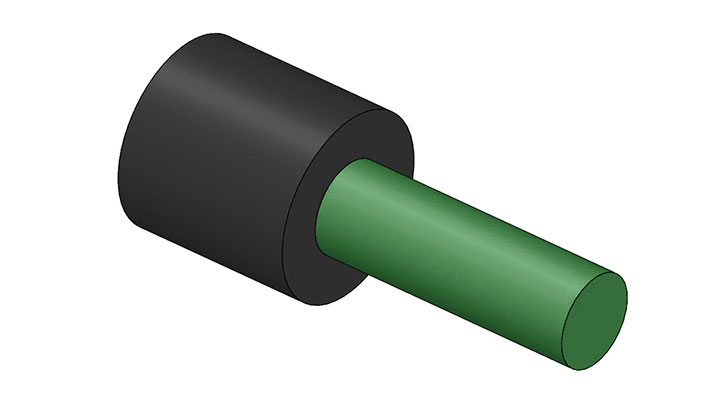

Press fitting is an assembly technique in which one object like a shaft is assembled to another by forcing it into a hole which is slightly smaller than the shaft. Press fit assembly techniques provide simple, fast and economical way to assemble plastic parts. Press fit can be designed for similar plastics or between dissimilar plastics or even between plastic and metals. Common example includes a plastic hub in form of a gear or control knob which is pressed on a metal shaft or a plastic sleeve or bearing which is pressed into a metal bore.

In press fitting the degree of interference between the two mating parts is critical. If it is too small then the joint is insecure and if it is too large then the joint is difficult to assemble and metal will be over stressed. A press fit remains permanently stressed and elastic deformation of the part provides the required force to hold the parts together.